Abstract

Every household uses an average of around 360 litres of water each day. About 21% of a typical gas consumption is attributed to heating the water for showers, baths, and hot water from the tap. An environmentally friendly, low-cost device called the CombiSave valve can be used to manage gas and water consumption and should be fitted to most combination boilers to automatically control the flow of water every time a hot tap is turned on. This allows the boiler to heat the water faster and only return the flow to normal once a usable temperature is reached. An experimental test was conducted in the exemplar modern house of Liverpool John Moores University in order to assess the amount of water, energy, and CO2 reduction for varying temperatures and flow rates. The test was carried out for a duration of 9 hours during the daytime between June and October. Although the test was conducted over relatively warm months when ambient water temperatures were higher compared to winter months, results showed that good savings could be achieved through this product. The best savings for gas consumption and hence CO2 reduction were achieved at high water pressure and low temperature setting (40 ℃) of 36% compared with the case without combiSave. While water consumption was reduced by 56% at full flow rate and 45 ℃. Further research is needed encompassing multiple occupied dwellings with different family sizes and testing these in extreme weather conditions to see if similar results would be reflected.

Keywords

1. Introduction

Water is a scarce and precious resource and is one of the 17 rather than 20 in 2015 Sustainable Development Goals (SDGs) that were launched in 2015. In 2006 the International Water Management Institute reported that a fifth of the world's population lived in areas that are facing water scarcity and this is expected to rise to 40 percent by 2025. A United Nations task force on water has projected that by 2025 there will be 3 billion people facing water stress conditions. As water scarcity accelerates droughts are undermining nature's ability to replenish this resource that is crucial for the existence of life on earth.

Estimates indicate that each person may use as much as 150 litres of water a day, of which up to 33% is used for bathing, showering, and washing up[1]. Water-related energy intensity associated with the end use stage in an urban water cycle has been reported as 79% of total water-related energy use in Australia, 72% in California, U.S., and 96% in Ontario, Canada; in all cases, more than 90% of this is for water heating, including space heating[2]. Energy used in domestic hot water (DHW) accounts for 22% of household energy use in the UK[3], which costs around £80 per year[4]. According to the UK Environmental Agency[5], about 89% of total carbon emissions come from water-related operations, which were contributed by domestic water end use.

Furthermore, an increase in population is one of the biggest pressures on water resources. In England, it is expected that population will increase to 69.2 million by mid-2026[6]. Many of the growth areas are in places where the water environment and water supplies are already stressed. Projections suggest that if there is no action is taken to minimise demand and improve was supply, many areas may fail to meet demand targets by the 2050s under high greenhouse gas emissions and high population growth scenarios. Even low increases in population growth and medium climate change scenarios showed significant water supply deficits by the 2050s, especially in the south-east of England[7].

The United Nations Framework Convention on Climate Change (UNFCCC) has developed an approach aimed at demand-side energy efficiency activities to install water-saving devices in buildings from a Clean Development Mechanism (CDM) perspective[8]. Similar legislation and guidelines are being applied worldwide to tackle the issue of frequent interdependence between water and energy, which is commonly called the water-energy nexus. Recently, there has been more focus on the energy used for the water sector in terms of water and wastewater supply, disposal, and treatment and in terms of water consumption in residential and non-residential buildings[9].

There are recent advancements made in different low Carbon technologies for water heating include electric storage tank water heater, solar water heaters, air to water heat pump, geothermal water heating, gas fire, biomass water heater[10-13] however these are quite expensive although they provide a significant saving. A new prospective on the importance of energy efficient hybrid hot water system and cost-effective saving needs to be investigated. Indeed, some recent studies have been performed in order to reach this objective especially with the revolution of the concept of Phase Change Material (PCM)[14,15]. A study[16] investigates the potential electrical energy savings that can be achieved by applying optimal (schedule and temperature) control to energy-storing electric water heaters. This has been done by testing 30 water heaters for a period of 20 days, which results in a reasonable electrical energy saving. There are also studies where different types of DHW technologies were analyzed in existing buildings in terms of heat used[17] or where heat recovery from DHW used and water flow limiters were proposed to improve the energy performance[18]. An experimental research[19] was conducted in 12 objects (multifamily buildings and 3 thermal substations) assigned to three groups (A, B, and C), depending on the analysed feature of the domestic hot water system. This includes installation of temperature control valves (group B) and decreased the temperature of the hot water during the night hours (group C). The energy savings were found to be in the range from 8.5% to 49.5% for group B object and from 6.0% to 14.4% for group C object. However, to the best of the authors' knowledge, the studies[20] present field results of heat consumption for DHW, heat loss from circulation lines and methods to increase efficiency of DHW system in existing building are limited. A study[21] made consist of using a mixture inside the water tank driven by electrical power which could reduce the heating time about 20 min to heat water from 25 ℃ to 70 ℃.

From the reviewed literature, it can be conducted that significant energy is wasted due to heating, ventilation, air-conditioning or industrial processes. It is therefore very important to consider heat recovery systems for building applications, such as hot water[22,23]. This approach is widely used nowdays; however, it could be more expensive to apply.

A new device has been introduced in this paper called CombiSave, which is used to heat the water for domestic use. The novelty of this system is that it can be used in different environments compared with other hot water technologies, such as biomass, solar thermal, and heat pumps, as these systems are restricted by weather conditions and are expensive to run. The system can be used with an old boiler without the need to change the whole hot water system. CombiSave is unique from present products in the market due to the fact that it is simple to operate, cost-effective, has a very short payback period, and provides a good saving in energy consumption based on the current study. Furthermore, where a traditional thermostatic radiator valve (TR) needs to be attached to each radiator, CombiSave is a whole house solution. It is fitted onto the outlet pipe coming away from the combi boiler so all hot water dispensing taps and showers will get faster hot water delivery. It is "fit and forget" and can stay in place even if the boiler is replaced. The fitter does not need an industry qualification to install, as there is no invasive gas or boiler works required. CombiSave is suitable for DIY fit for a competent person.

The purpose of this study is to show the savings in water, energy, time and consequently carbon emission reduction that can be achieved by the use of the thermostatic valve 'CombiSave' in conjunction with a combination boiler in domestic dwellings. The amount of wasted water in homes due to waiting for water to heat up to the required temperature will be quantified.

2. Materials and Methods

2.1 CombiSave

The CombiSave is a self-acting, thermostatically controlled valve and therefore completely automatic. It is made from dezincification-resistant brass. It is fitted with two rotatable elbows, which allow for easy fitting to a range of 15mm pipe configurations and can be installed in different ways at 90°, Inline, and 180°.

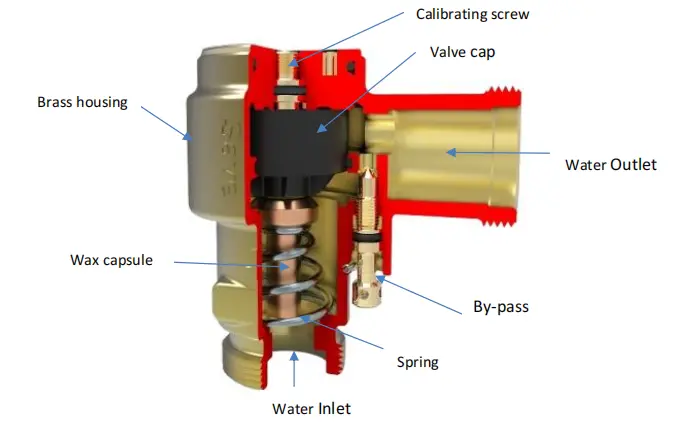

The unit is designed to fit between the combi boiler and the hot water tap outlet and control the flow of water during the combination boiler's initial firing process. The device head is fitted inside with a capsule filled with wax thermostat that expands and contracts based on the temperature changes (Figure 1). When the tap is turned on, water flows through the valve but at a restricted rate as it only passes through the by-pass hole. This gives the person using the tap the knowledge that water is running. To fire up the boiler, a flow is needed, and this is determined by setting the bypass screw at a position that ensures the boiler will fire up but not release full flow of water. Ordinarily, the boiler takes some time to heat the water to the desired temperature, and this results in delay and a flow of cooler water, which is generally discarded to drain. With a CombiSave valve, the operation of the wax capsule reduces the flow rate until water is at the desired temperature. When the set temperature is reached, the wax expands as it detects the temperature of the water passing over it and pushes the operating rod up the bottom of the calibrating screw. This forces the valve cap to be pushed down, which then enables water to pass through it at full rate and out through the water outlet. The tap will then display normal water flow. This reduces the amount of energy used at the initial warming stage and limits the amount of water run to waste. It can even be fitted to older boilers, so it's one of the best ways of making homes more energy efficient without buying a brand new model.

2.2 Experimental setup

The experiment was conducted in an unoccupied domestic dwelling on the Liverpool John Moores University campus grounds that has been purpose built for conducting tests and experiments. The tests were run over a 4-months period from June to October and during the hours of 9am and 6pm. During this period the CombiSave functioned at the halfway stage and had to be replaced before tests proceeded and there were no further problems. The combi-boiler in the house had an 'A' rating and had been recently serviced.

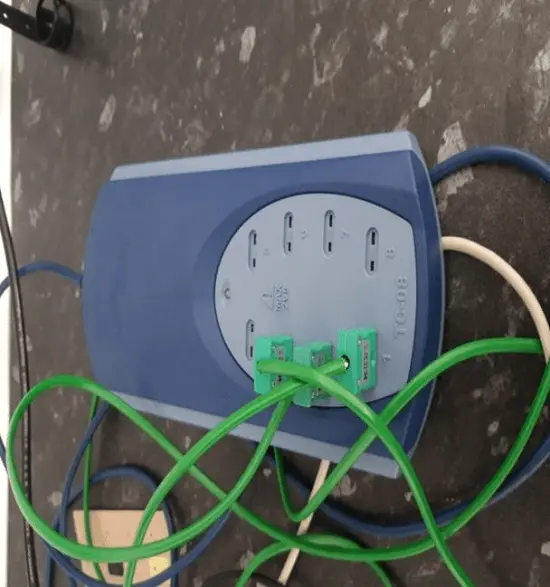

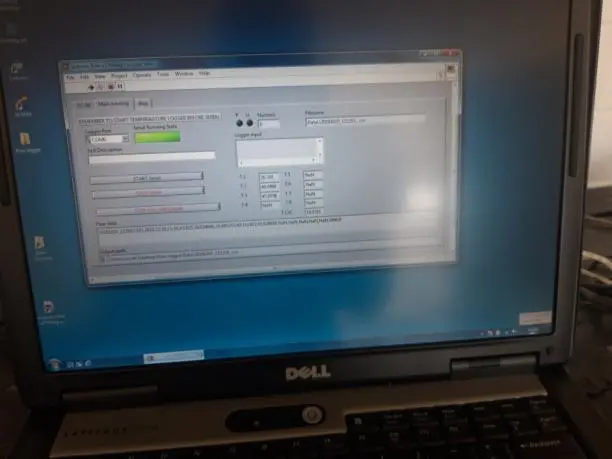

This research was carried out using primary quantitative data gathered from tests conducted in the Eco exemplar house and secondary research involving literature reviews. The equipment installed for the experiment were a CombiSave valve which was fitted to a Viessmann combination boiler, three temperature sensors were installed one on the mains water pipe into the boiler, the other on the hot water pipe leaving the boiler and the third on the hot water tap in the kitchen which represented the point of use. A GEMS flow sensor was connected to the hot water outlet in the kitchen to measure amount of water used per second. Also, a Davis Vantage Pro 2 weather monitor was also used to measure and monitor outdoor temperature in ℃. Experimental setting has been shown in Figure 2, Figure 3 and Figure 4.

The amount of water used, the time taken to heat it to a set temperature and the amount of gas used when the CombiSave is in use were compared to the condition when the CombiSave is not in use. The data were collected and stored by the data logger that recorded the different parameters when the temperature increased.

The experiment was conducted by taking the following steps:

• Taking gas reading before commencing experiment.

• Turning Arduino software on to measure flow rate and water temperature changes.

• Turn the hot water in the kitchen and let it run until it reaches a set temperature.

• Turn hot water off and the Arduino software off. Save the data collected and then record reading on gas meter.

• Set the heating temperature on the boiler to minimum and then manually raise temperature setting on room thermostat to 1 degree above room temperature. This allows the hot water inside the boiler to be flushed out but as the boiler temperature is set at minimum, it will not fire up to heat the water.

• When the boiler temperature goes down from 78 to below 30 this indicates that the water in the boiler system is now cold. Manually set the temperature on the room thermostat to minimum to switch off the boiler.

• Turn the electricity supply to the boiler off and then turn the cold water in the kitchen on to flush out any hot water in the pipes. When the temperature sensors are recording the same temperatures as they were at the beginning of the experiment this indicates that all hot water has been flushed out in both the boiler and pipework and the experiment can be run again.

• Turn the electricity to the boiler back on.

• Repeat the above procedures with the CombiSave valve turned on. Save data from the data logger to show time it takes to reach set temperature and amount of water that was used before desired temperature is reached.

• Repeat the experiment using different CombiSave temperature settings and water pressure settings.

These steps were repeated several times on different days and at different times of the day over a 4- month periods. Data collected included gas consumption, Water consumption, boiler run time, Incoming water temperature, time for water to heat up and water flow rate.

Overall, three different scenarios were tested during the experiment. The first scenario (scenario A) was to test how long it took to heat water and the amount of water used before desired temperature is reached without the use of the CombiSave valve. Scenario B was with the CombiSave valve half open to simulate reduced water pressure. Scenario C was with the Combisave valve fully open to simulate maximum water pressure. Three CombiSave temperature set points were tested for and these were 40 ℃ (minimum Combisave setting), 45 ℃ (medium setting) and 50 ℃ (maximum setting).

3. Results & Discussion

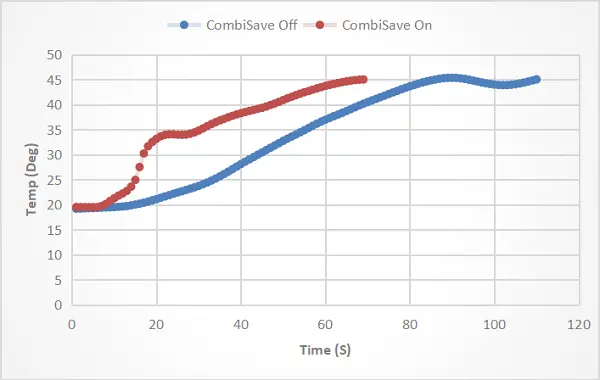

The graph in Figure 5 indicates that the CombiSave valve had a noticeable saving in the time it took for the water to heat up to the desired temperature (saving was estimate as an average of one day consumption for the kitchen tab). The CombiSave valve restricted water flow for an average of 30 seconds during which time the temperature increased rapidly. After the CombiSave valve was activated the rate of temperature increase was reduced but the water had heated up significantly to allow a time saving in water heating to the required temperature.

Figure 5. Time consumed through use of a CombiSave at different temperature setting.

Results from Table 1 showed that the CombiSave offered the best savings at high water pressure and low temperature setting. The average savings on gas consumption and greenhouse gas emissions when the CombiSave valve was used were up to 36%. Table 1 also shows that it can take up to twice the time to heat water to the required temperature compared to when a CombiSave valve is used. Table 1 shows gas consumption conversion from cubic metres to kilowatts per hour. A conversion factor of 0.18296 was used (UK carbon conversion factor) to calculate the carbon dioxide equivalent of the average greenhouse gases emissions when the CombiSave valve was used in comparison to when it was not used.

| Scenarios | CombiSave Settings | Temperature Settings (C) | Time (Sec) | Gas Consumption (m3) | Gas Consumption (Kwh) | CO2 Equivalent (kg) | CO2 Saving % |

| Scenarios A1 | CombiSave off | 40 | 03:15 | 0.16 | 1.78 | 0.33 | |

| Scenarios A2 | CombiSave half on | 40 | 02:55 | 0.12 | 1.34 | 0.25 | 25 |

| Scenarios A3 | CombiSave full on | 40 | 00:58 | 0.102 | 1.14 | 0.21 | 36 |

| Scenarios B1 | CombiSave off | 45 | 03:30 | 0.14 | 1.56 | 0.29 | |

| Scenarios B2 | CombiSave half on | 45 | 03:08 | 0.13 | 1.45 | 0.27 | 19 |

| Scenarios B3 | CombiSave full on | 45 | 01:23 | 0.12 | 1.34 | 0.25 | 25 |

| Scenarios C1 | CombiSave off | 50 | 04:04 | 0.17 | 1.89 | 0.35 | |

| Scenarios C2 | CombiSave half on | 50 | 03:38 | 0.14 | 1.56 | 0.29 | 17 |

| Scenarios C3 | CombiSave full on | 50 | 02:57 | 0.13 | 1.45 | 0.27 | 22 |

* CO2 e conversion factor = 0.18396

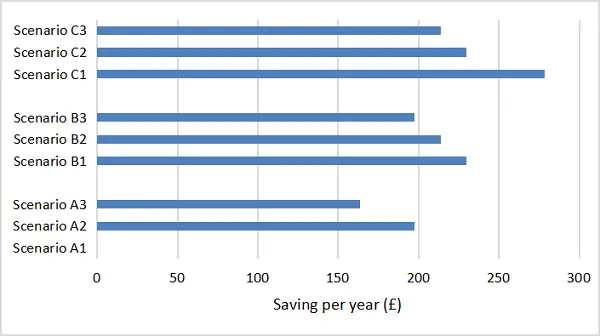

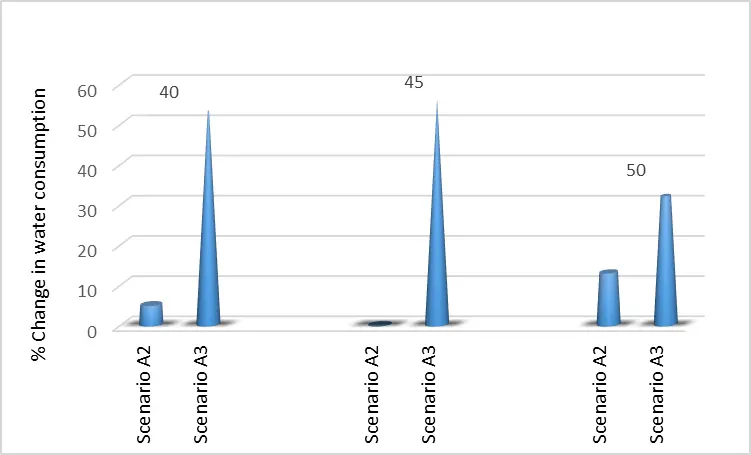

Figure 6 shows that water savings of up to 56% can be achieved when heating water to the desired temperature with the use of a CombiSave device. The greatest water savings were achieved with the CombiSave bypass fully closed (i.e., CombiSave full on). Having the CombiSave half on did not result in a significant water saving, which suggests that this does not change the water pressure. Furthermore, annual cost has been considered as in Figure 7, which reflects that the new unit has a descent running cost reduction.

Figure 6. Percentage average water consumption saving per day under 3 temperature settings and 2 flow runs.

The experiment was conducted in an unoccupied exemplar house, so scenarios that simulated the experiment were limited in the way that they could accurately reflect water usage in an occupied dwelling. However, it still provides good initial findings in terms of the combi save efficiency.

The experiment was conducted over the summer when the mains water temperature was likely to be higher than in winter. As a result, the savings achieved by the CombiSave may not be as high as they could be in winter. It is recommended that the experiment be conducted in winter to compare the results and determine if ambient water temperature has an effect on the savings that can be achieved from using a CombiSave valve in summer compared to winter.

The water usage savings were significant but not as great as had been expected. A possible explanation for this is that water consumption was measured up to the time the set temperature was achieved rather thanwhen the CombiSave released the full water flow.

4. Conclusion

This paper provides an initial findings analysis of the relationships between water consumption, gas used, and carbon emission savings that are possible through the use of the low-cost CombiSave device. Analysis of data collected shows that the use of a CombiSave valve clearly results in a saving of water and energy consumption. The technology will be crucial in providing solutions to compact water waste and the associated energy consumption, which in turn will result in carbon emission savings. The experimental tests were run with and without a CombiSave in order to evaluate their effect as a reduction on the building heating energy consumption. The results show that the use of a CombiSave valve can reduce total heat related energy and thus carbon emissions during a complete heating season up to a maximum of 14% for the current case study. Results also confirmed that the use of a CombiSave valve is a low investment retrofit measure that can be easily installed in domestic dwellings that have a combi-boiler installed.

Although the testing methodology was limited in its scope, it yielded reliable results that are consistent with how the CombiSave valve was expected to perform. For more accurate results to be achieved it would be necessary to install the CombiSave valves in multiple domestic dwellings that are occupied by different size families. This would enable the collection of more data that can be analyzed to show the effects of the CombiSave on different family sizes. Furthermore, the research was conducted over the summer months when ambient water temperatures were higher compared to winter months. It is contended that the CombiSave would achieves best results when the ambient water temperature is lower so future research needs to be conducted over a longer period of time to ascertain if ambient water temperature has an effect of the savings that can be achieved using a CombiSave valve.

Authors contribution

Abdellatif M: Draft writing and supervision.

Muzhona B: Experiment and analysis.

Furlong D: Conceptualization.

Osman Y, Cullen J, Brady L: Supervision.

Conflicts of interest

Mawada Abdellatif is an Editorial Board member of the journal and other authors declare that there are no conflicts of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Availability of data and materials

The data could be obtained from the corresponding author.

Funding

None.

Copyright

© The Author(s) 2024.

References

-

1. Odurinde T. UK household water consumption 2015: facts & figures [Internet]. Hope Spring Water; 2015 Oct 12 [cited 2024 Jul 4]. Available from: https://www.hopespring.org.uk/uk-household-water-consumption-2015-facts-figures

-

2. Plappally A, Lienhard JH. Energy requirements for water production, treatment, end use, reclamation, and disposal. Renew Sustain Energ Rev. 2012;16:4818-4848.

[DOI] -

3. Department for Business, Energy & Industrial Strategy (UK). UK energy in brief 2021 [Internet]. London: Department for Business, Energy & Industrial Strategy; 2021 [cited 2024 Jul 4]. Available from: https://assets.publishing.service.gov.uk.pdf

-

4. Energy Saving Trust. Why we should all be saving water [Internet]. 2020 May 10 [cited 2024 Jul 4]. Available from: https://energysavingtrust.org.uk/why-we-should-all-be-saving-water

-

5. Environmental Agency. Greenhouse gas emissions of water supply and demand management. Science Report No. SC070010 [Internet]. Bristol (UK): Environmental Agency; 2008 [cited 2024 Sep 30]. Available from: https://assets.publishing.service.gov.uk.pdf

-

6. Office for National Statistics (UK). Office for National Statistics homepage [Internet]. Newport (UK): Office for National Statistics; [cited 2024 Sep 30]. Available from: https://www.ons.gov.uk

-

7. HR Wallingford. Update analysis of the number of properties located in areas at risk of flooding and coastal erosion in England [Internet]. Report for the Adaptation Sub-Committee; 2015 Jun [cited 2024 Sep 30]. Available from: https://www.theccc.org.uk/wp-content/uploads/2015/06/MCM7406-RT001-R02-00-low-res.pdf

-

8. European Commission. Water performance of buildings [Internet]. Brussels (Belgium): European Commission; 2012 [cited 2024 Jul 20]. Available from: http://ec.europa.eu/environment/water.pdf

-

9. Nair S, George B, Malano HM, Arora M, Nawarathna B. Water-energy-greenhouse gas nexus of urban water systems: Review of concepts, state-of-art and methods. Resour Conserv Recycl. 2014;89:1-10.

[DOI] -

10. Wang Z, Guo P, Zhang H, Yang W, Mei S. Comprehensive review on the development of SAHP for domestic hot water. Renewable Sustainable Energy Rev. 2017;72:871-881.

[DOI] -

11. Niemelä T, Manner M, Laitinen A, Sivula TM, Jokisalo J, Kosonen R. Computational and experimental performance analysis of a novel method for heating of domestic hot water with a ground source heat pump system. Energy Build. 2018;161:22-40.

[DOI] -

12. Hohne PA, Kusakana K, Numbi BP. A review of water heating technologies: An application to the South African context. Energy Rep. 2019;5:1-19.

[DOI] -

13. Abdellatif M, Baynesb S, Osman Y, Brady L, Cullen J, King D. Experimental investigation of Versa Tyle GRP for solar thermal system. Int J Green Energy. 2021;18(1):90-99.

[DOI] -

14. Lu S, Zhang T, Chen Y. Study on the performance of heat storage and heat release of water storage tank with PCMs. Energy Build. 2018;185:1770-1780.

[DOI] -

15. Deng J, Furbo S, Kong W, Fan J. Thermal performance assessment and improvement of a solar domestic hot water tank with PCM in the mantle. Energy Build. 2018;172:10-21.

[DOI] -

16. Booysen MJ, Engelbrecht JAA, Ritchie MJ, Apperley M, Cloete AH. How much energy can optimal control of domestic water heating save? Energy Sustainable Dev. 2019;51:73-85.

[DOI] -

17. Binks AN, Kenway SJ, Lant PA. The effect of water demand management in 604 showers on household energy use. J Cleaner Prod. 2017;157:177-189.

[DOI] -

18. Kordana S, Słys D, Dziopak J. Rationalization of water and energy consumption in shower systems of single-family dwelling houses. J Cleaner Prod. 2014;82:58-69.

[DOI] -

19. Cholewa T, Siuta-Olcha A, Anasiewicz R. On the possibilities to increase energy efficiency of domestic hot water preparation systems in existing buildings - Long term field research. J Cleaner Prod. 2019;217:194-203.

[DOI] -

20. Bohm B. Production and distribution of domestic hot water in selected Danish apartment buildings and institutions. Analysis of consumption, energy efficiency and the significance for energy design requirements of buildings. Energy Convers Manage. 2013;67:152-159.

[DOI] -

21. Faraja J, Harikac E, Akoumb M, Murrc R, Khaledlal Faraj. Enhanced Residential Water Heater: Experiments and Analysis. Energy Procedia. 2019;162:164-170.

[DOI] -

22. Mardiana-Idayu A, Riffat SB. Review on heat recovery technologies for building applications. Renewable Sustainable Energy Rev. 2012;16:1241-1255.

[DOI] -

23. Jouhara H, Khordehgah N, Almahmoud S, Delpech B, Chauhan A, Tassou SA. Waste heat recovery technologies and applications. Thermal Sci Eng Prog. 2018;6:268-289.

[DOI]

Copyright

© The Author(s). This is an Open Access article licensed under a Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, sharing, adaptation, distribution and reproduction in any medium or format, for any purpose, even commercially, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Share And Cite