Abstract

A detailed quantitative overview on different micro-electro-mechanical systems (MEMS) smart glass technologies and smart glass technologies in general is given. Next, our MEMS smart glass is focused. This technology based on millions of miniaturized, tiltable, planar mirrors. Installed in windows or building facades, it allows personalized daylight steering as well as thermal and energy management in buildings via electrostatic actuation, strongly supports health and has a large potential for reducing CO2 emissions and energy consumption of buildings, noticeably. Various results of experimental characterizations and reliability studies are summarized. Simulations of light steering are reported for different use cases involving tailored variable tilt angles of the mirrors. Ray tracing is used to visualize light steering and distribution in a model room, showing that our MEMS smart glass can generate high illuminance where necessary in workspaces. Finally, simulations of energy savings are presented using hourly resolved real weather data over up to 10 years, varying cloud coverage, daytime and seasonal varying irradiance via varying sun orbit, respective geo coordinates of different locations, energy price and others. Simulation results are depicted for four German and two international cities, varying in latitude and elevation. Huge energy saving potential of our MEMS smart glass and amortization of investment in MEMS smart glass within less than five years in the best case is reported compared to conventional window blind systems.

Keywords

1. Introduction

Over the last decades the negative influence of humanity on global climate has become consensus in the scientific community. Above all, the emission of greenhouse gases was identified as the driver of global warming[1]. Climate change has caused several negative aftereffects on the entire planet like global warming, the swift increase in sea levels at a rate of 3.3 mm annually, and adverse effects on human health stemming from an unstable ecosystem[2-4]. Due to increasing negative influence on mankind the topic had also come into public eye in recent years which has resulted in a rethinking in the climate policy of many states[5]. As per the “Paris Agreement” of 2015[6] signed by 54 countries, including Germany, it is imperative to implement effective measures informed by cutting-edge science and technology to fight the challenges posed by climate change. Despite that, the global anthropogenic greenhouse gas emission in the last decade (2010-2019) increased compared to the former[1]. This ever-increasing trend will persist and intensify unless immediate steps are taken to implement countermeasures[2-4]. Moreover, it was declared that a substantial reduction in the risk of climate change can be achieved by limiting the global average temperature increase to within 2 °C. When exploring alternative methods of energy production beyond conventional techniques, renewable sources such as Wind, Water, and Sunlight are regarded as primary resources with the potential to conserve a significant portion of Earth’s energy, replacing the need for fossil fuels[7].

Globally, existing buildings alone account for the largest share of energy consumption, accounting for 50%, leading to huge CO2 emissions. Additionally, a vast majority of building stocks are energy inefficient, with only a minimal percentage undergoing renovation each year[8-10]. The report from the German Federal Ministry for the Environment, Nature Conservation, and Nuclear Safety in March 2021 disclosed that, from 1999 to 2020, buildings surpassed the manufacturing and energy industries to become the third-largest contributors to CO2 emissions[11]. As per the “Building Report KOMPAKT 2019” by the German Energy Agency, space and water heating, along with lighting, are identified as the primary factors contributing to energy consumption in buildings[12]. Windows and glazing are integral components of buildings, serving a crucial role in ensuring effective insulation by minimizing heat loss and harnessing solar heat. They also provide natural light, ventilation, and pleasant outdoor views for occupants. Adjusting solar heat gain can enhance the energy efficiency of windows when compared to standard walls. However, a significant portion of glazing worldwide lacks energy efficiency, often featuring single glazing or early double glazing without low-emissivity (low-e) coatings[13]. Furthermore, windows are often regarded as the least energy-efficient component of a building, as they account for a major portion, approximately 60% of total energy loss due to heat conduction, convection, and radiation. This inefficiency translates into increased energy demands for both heating and cooling purposes[14].

The concept of ‘Smart Green Buildings’ has gained significant attention recently, emphasizing the importance of incorporating energy-efficient equipment in all buildings while increasing the use of renewable energy sources within the national energy mix. Nevertheless, optimizing energy consumption and its simultaneous reduction through readily available natural resources, such as utilization of solar radiation for lighting, heating, and cooling, will play a pivotal role. Earlier misconceptions about daylight having no discernible positive impact on human health and workplace hygiene, which may have contributed to the widespread adoption of artificial lighting, have now been re-evaluated from a more practical perspective. This shift in viewpoint is leading regulatory standards to place greater emphasis on occupational health over the visual performance[15]. For example, among numerous recent studies, the “Light and Health” investigation conducted in 1990 stands out as a comprehensive analysis that took various factors into account. This study proves that workers near the vicinity of windows within a commercial building encounter the lowest levels of health risks since they experience reduced fatigue, dizziness, job dissatisfaction, depression, tension, and disruptions in their natural working rhythm[16]. Hence, daylight is favored over artificial lighting because of its availability, illuminance with a full spectrum, variation in incident angles, as well as color and intensity. These attributes have a multitude of positive effects on human health and well-being like driving proper fundamental biological processes, reducing the risk of myopia by a factor of five, and shortening the hospitalization periods for patients with severe and refractory depression, among other benefits, as presented by numerous studies[17,18].

2. Smart Glass Overview

2.1 Comparison of smart glass technologies

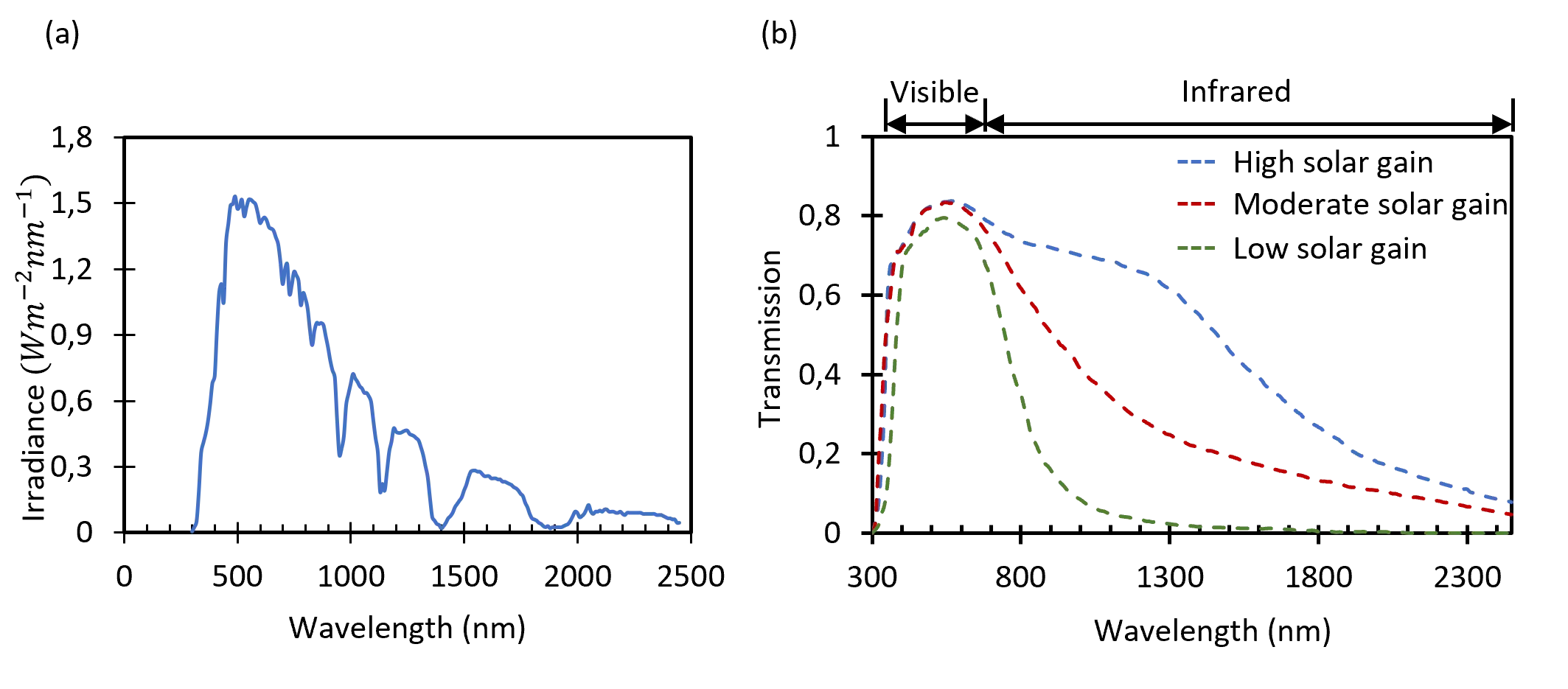

Architects have overcome the historical reluctance to incorporate extensive window areas into building designs due to concerns about higher thermal transmittance values compared to opaque building elements. A contemporary trend in recent years involves pushing the envelope by implementing a higher Window-to-Wall Ratio (WWR) in building facades, often surpassing regulatory standards. This is achieved through the use of high-performance glazing systems, inc luding dynamic switching, to harness sunlight effectively and meet energy demands. In the European Union (EU), for instance, the WWR in buildings has doubled since 1980[13]. Various research studies have consistently demonstrated that harnessing daylight through a high WWR holds the greatest potential for achieving significant energy savings and, consequently, significant reductions in CO2 emissions[14-16,19,20]. Nonetheless, a high WWR introduces a significant drawback for building occupants, primarily excessive glare caused by uncontrolled daylighting at unfavorable angles. To mitigate these issues, window blinds are commonly employed to regulate uncomfortable incoming light. However, this often requires artificial lighting to compensate for the reduced natural light due to the employment of window blinds. Moreover, due to the common practice of placing the windows on one side of the room, only nearby areas are illuminated by the natural illumination, leaving distant sections darker and more reliant on artificial lighting to achieve a consistent light distribution across the entire room space. A numerous number of smart window technologies have been developed based on the features of the optimum daylighting technologies. Many of these technologies are now currently available in the commercial market. For example, sun shading systems like photochromic, thermochromic, electrochromic, and gasochromic systems, together with active window systems like Polymer Dispersed Liquid Crystal Display (PDLC), Suspended Particle Devices (SPD), as well as light steering systems such as light shelves, window blinds and light directive films, have been developed to eliminate the disadvantages of uncontrolled daylighting[17,18,21].

In an optimum daylighting system, maximum utilization and homogeneous distribution of daylight, flexibility to satisfy distinct light requirements, lighting, cooling and heating load reduction, efficient, clear view through, higher switching speed, low maintenance requirement and power consumption, as well as cost-effective manufacturing, installation and usage, are expected. Excellent homogeneities of the material thicknesses and compositions, high material purity to avoid unwanted absorption, a low minimum transmissivity Tmin (closed state), high maximum transmissivity Tmax (open state), large modulation contrast Tmax/Tmin, high switching speed, low haze, low temperature sensitivity, long lifetime, and low sensitivity for solar UV radiation are considered as important characteristic parameters. However, the above mentioned smart window technologies fulfil the requirements only to a very limited extent.

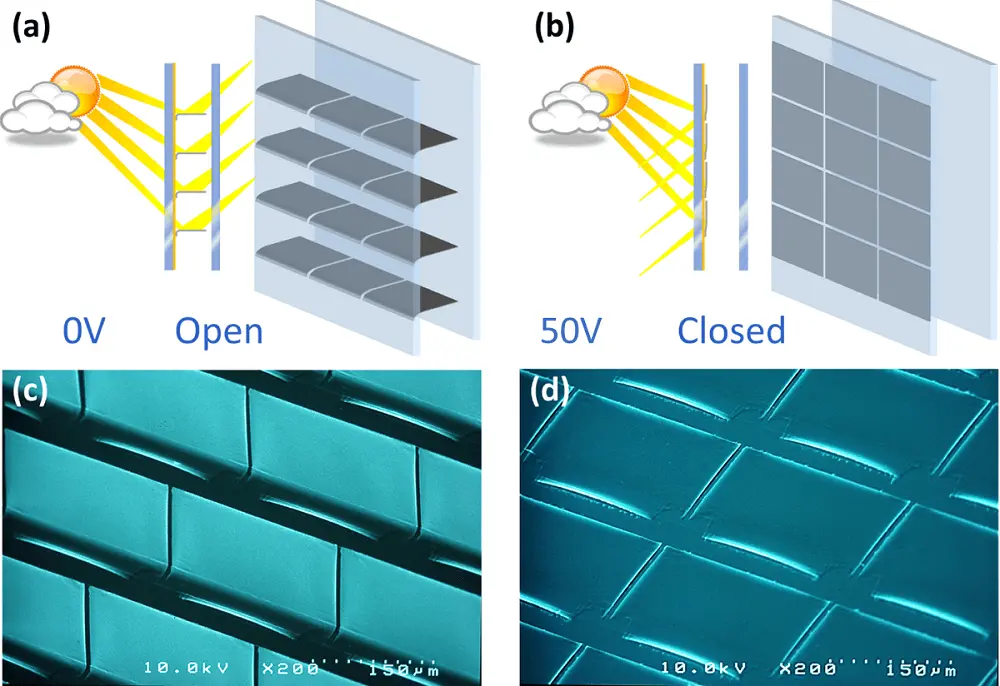

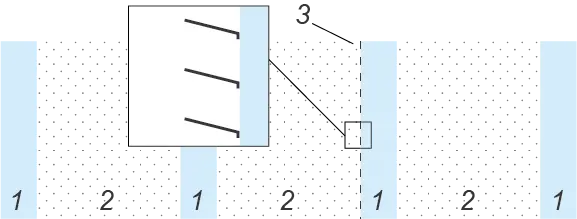

With the aim of efficient utilization of daylight in the best possible way, intelligent smart window technology comprised millions of electrostatically actuatable (MEMS)-based micromirrors inside double glazing windowpane (Figure 1) in an inert gas (argon, krypton or xenon) environment has been developed at the Institute of Nanostructure Technologies and Analytics (INA), University of Kassel[19,20,22-29]. The micromirrors arranged within the windowpane are protected from dust, damage due to strong wind, window cleaning, and adverse weather conditions which increases the lifetime and overall stability. These miniaturized micromirrors, which are imperceptible to the naked eye from distances greater than 25 cm, have long lifetime, high stability, low power consumption capability, high energy saving potential[16], cost effectiveness, fast switching speed and large operating temperature range.

Figure 1. Micromirror in open (0 V, (a), (c)) and close (50 V, (b), (d)) state, from a side perspective. They are arranged in an inert gas atmosphere inside insulated double-glazed windowpane and sealed with butyl, as illustrated in (a) and (b) as schematic diagram and their respective SEM micrographs in (c) and (d). Reproduced with permission from[16]. SEM: scanning electron microscopy.

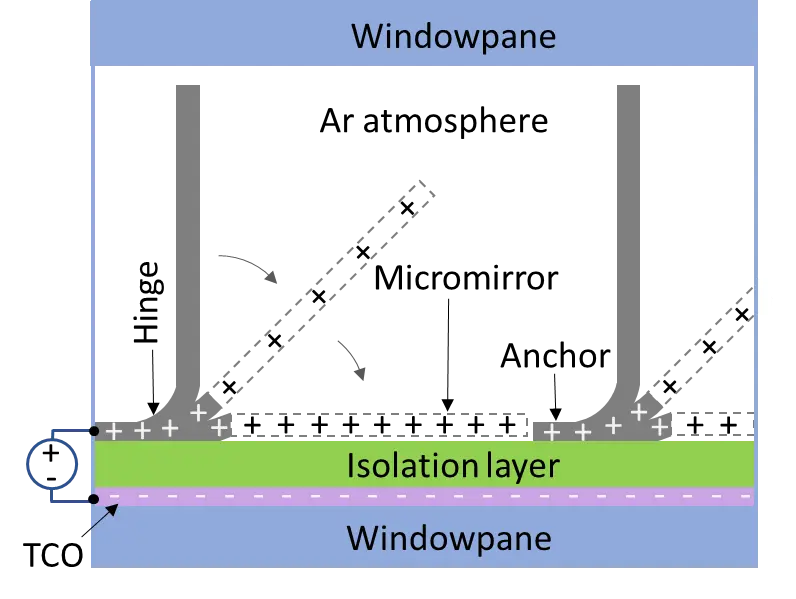

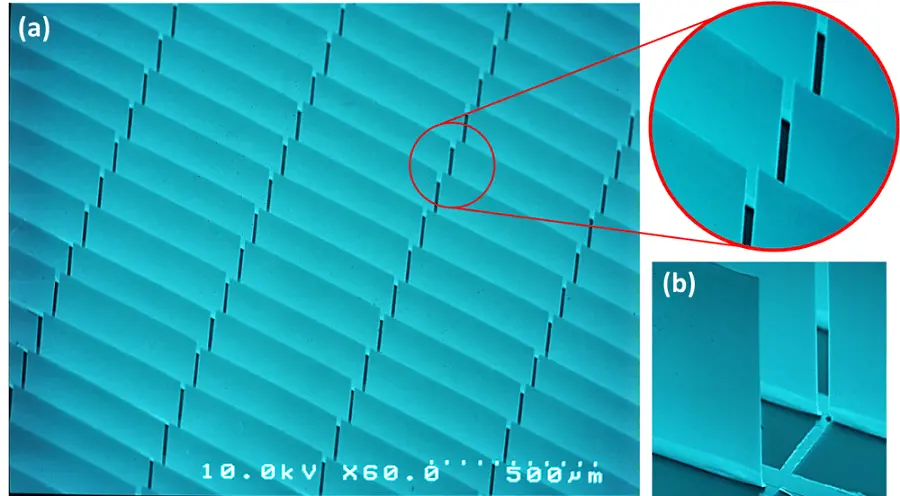

The individual micromirror with three primary parts; anchor, hinge and mirror plane, is fixed at one side—nearly identical to a hinged door. Micromirror is made of a combination of aluminium-chromium-aluminium-aluminium in multi-layer stack formation. The residual stress presence in the multi-metal thin layers at the hinge area is responsible for the deflection of free standing micromirror at an angle of 90° with respect to the substrate (Figure 2 and Figure 3) with a flat mirror plane due to localized stress compensation. When the potential difference is applied between the mirror plane and counter bottom electrode, the micromirror can be held in different intermediate angles (tilting angle Φ) by balancing the electrostatic attraction force and restoring force induced by the residual stress, before it reaches the critical pull-in angle where it snaps horizontal to the substrate due to the well-known pull-in or snap-in effect. This principle enables dynamic light guiding via active control of reflection on the mirror surface. The recent development of 2D actuation in micromirror array - generating two angles, tilt Φ and torsion θ by optimum structured Transparent Conducting Oxide (TCO), which allows the tailored adjustment of electrostatic force[22,28]. This new generation of micromirrors enables efficient light steering throughout the day independent of the window orientation, user movement and sun position.

Figure 2. Schematic representation of an individual micromirror actuation concept in between the panes of a window glazing in an inert gas environment. Reproduced with permission from[16].

Figure 3. SEM micrograph of (a) free standing micromirror arrays after lift-off and drying process with an inset of a magnified area, (b) individual vertical standing flat mirror with ~90° opening angle. Republished with permission from[16]. SEM: scanning electron microscopy.

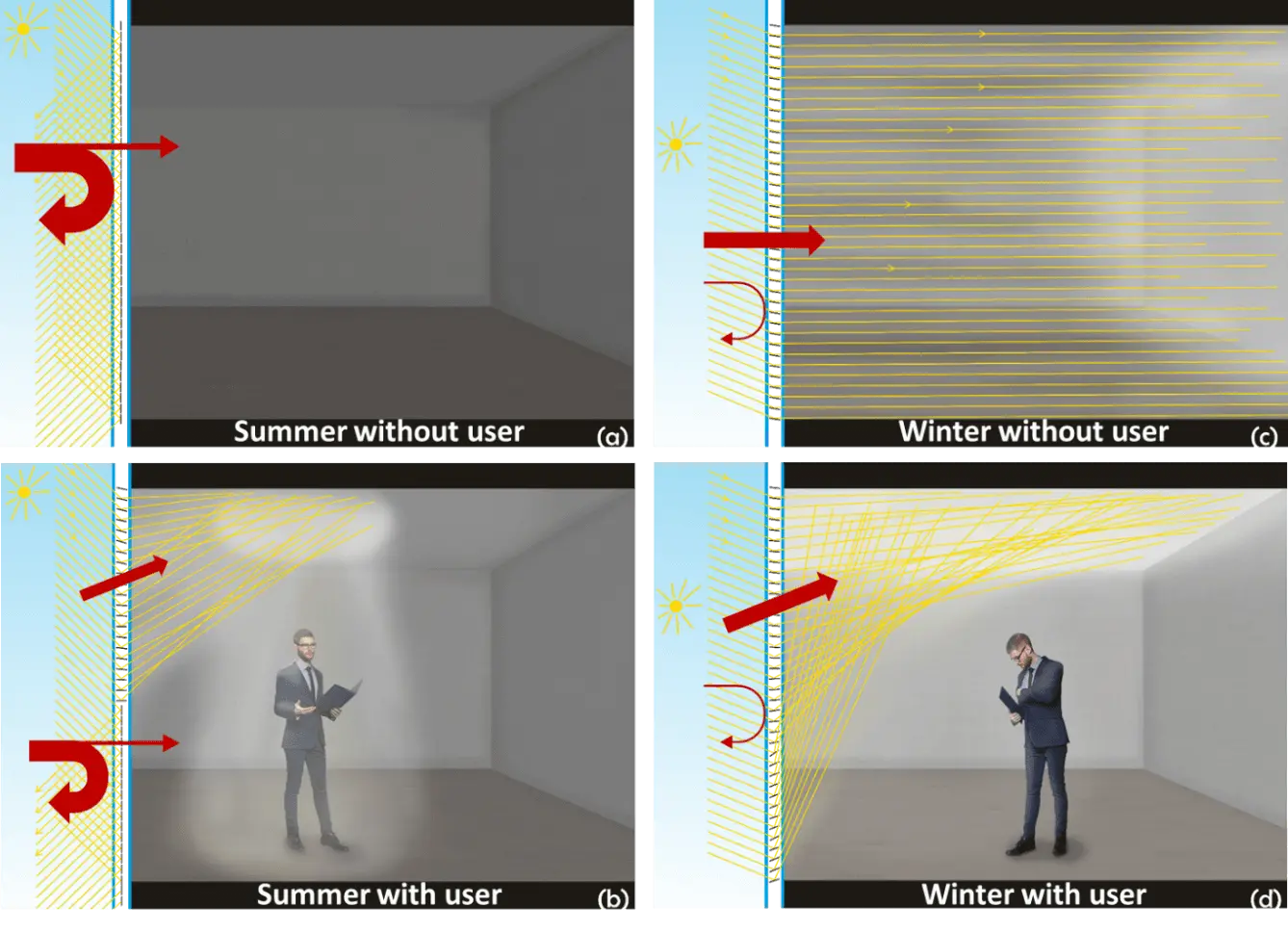

Based on the window orientation, latitude of the building, season, daytime and user presence, a nearly unlimited number of scenarios are possible. Four of those scenarios are displayed in Figure 4: Two of the micromirror states enable daylight guiding by explicit reflection towards the ceiling in the room, one reflection scenario to a wall and a completely closed state where the micromirrors are parallel to the windowpane due to electrostatic force to block the solar radiation. The solar radiation is reflected outside by switching all the micromirrors vertically in summer (very high solar impact) without any user in the room to keep the room cold. An automated control unit with data from an intelligent network sensing system that observes the position of persons, sun position, inside temperature and light ambience is therefore fed to execute the functionalities according to the requirements. During summer, when there is no user in the room, all the micromirrors are placed in closed position (parallel to the windowpane), saving huge cooling energy by minimizing the heat transfer into the room (Figure 4a). When user presence is detected during summer, some of the micromirrors (upper areas in Figure 4b) are kept open to reflect light towards the ceiling area above the user. However, the lower micromirrors are closed to keep the unoccupied room area, cool thus allowing energy saving by limiting the heat transfer into the room since only a certain number of mirrors are open.

Figure 4. Illustration of a room equipped with a micromirror-array-based smart window and scenarios with and without users in different seasons, demonstrating light steering and heat energy management. (a) Summer, no user present: solar radiation is blocked by reflecting outside that keeps the room cool and saves huge energy; (b) Summer, user present: illuminates by deflecting light towards ceiling above the user and saves energy by limiting the heat transfer with closed micromirror in the lower areas; (c) Winter, no user: acts as a radiation heater by using all solar infrared and visible radiation to heat up the room; (d) Winter, user present: complete solar radiation is reflected towards the ceiling. Heat radiation coming inside the room is presented with red arrows. The widths of the red arrows symbolize the amount of heat energy, entering the room or being harvested, respectively. Republished with permission from[16] with permission of Leuze publishing house.

In addition, the illuminated spot on the ceiling can be moved with the user; thus, the inside area far away from the window can also be illuminated efficiently (Figure 4b). During winter with no user detected in the room, all the micromirrors are open to harvest energy efficiently by using the whole solar radiation to keep the room warm, similar to thermal component activation, thus saving the huge amount of energy required for heating (Figure 4c). When a user is present during winter, the solar radiation is directed towards the ceiling by keeping all the micromirrors open, however, with different angles using tailored actuation voltages. This saves energy needed for heating and lighting at the same time (Figure 4d). The general methodology, technological fabrication process, implementation of subfield addressing, reliability experiment, concept of clear view through have already been studied and reported in details[19,20,22-29].

Until now only flat windows installed in a 90° orientation in relation to the ground are discussed but windows are also installed in different orientations and the modules can be curved:

• Tilted but flat panes can be actuated in a similar way. After installation of the window, the tilt angle has to be entered into the smart glass control system. This is very simple if the tilt angle remains constant. In case the angle also varies, a tilt angle sensor has to be installed in addition to guarantee proper light steering via the MEMS smart glass.

• At the moment we also have fabricated and characterized MEMS smart glass on polymer foils[26], which can be bent easily in one direction but not in two.

• The process for MEMS smart glass on free-planes (2 bending directions or even more complex) has to be developed and is much more complex. This we will do in future for applications in e.g. cars and other mobile systems.

• Note that curved reflective glass can be potentially dangerous. And may inadvertently concentrate sunlight and melt materials on the opposite side of the street, as observed in certain instances by the Walkie-Talkie building (London UK), and the Walt-Disney concert hall (Los-Angeles USA)[30]. Thus, we would prefer flat panes if not desired by the customer, explicitly. Since the reflections of flat panes with closed reflective mirror array can reflect and illuminate other parts maximum with the intensity of direct sun light.

• We also developed another novel MEMS smart glass design using two different surface functionalities on the two sides of the mirror, to reduce reflections and avoid potentially dangerous situations outside in e.g., the traffic[29].

• We also developed curved micromirror arrays on polymer substrates[26].

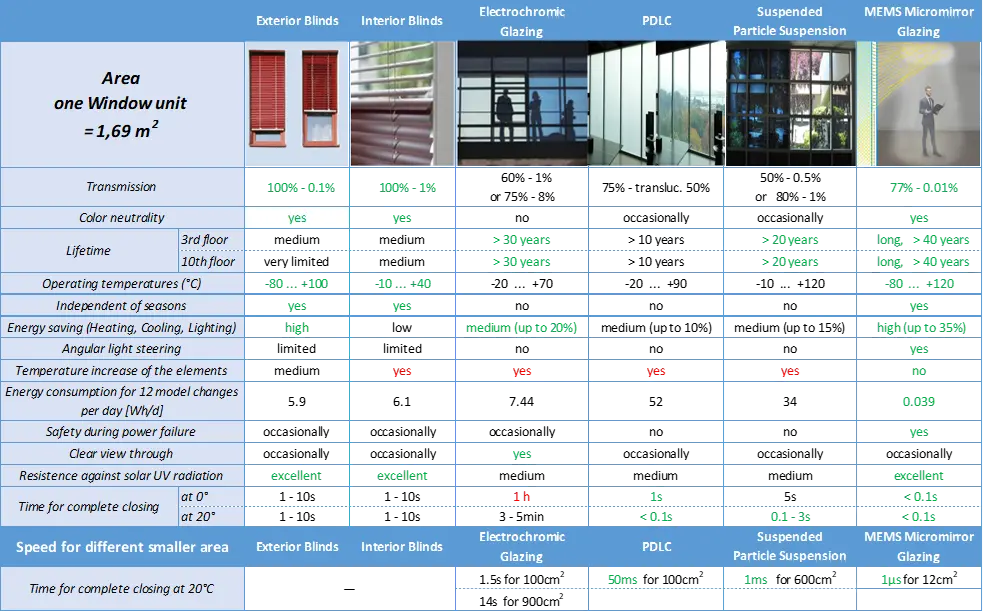

A characteristic comparison of commercially available smart windows and our MEMS smart window is presented in Figure 5. Regarding transmission, the highest contrast between maximum and minimum transmittance is about a factor of 1,000 for conventional blinds and 7,700 for the MEMS smart glazing. On the other hand, all the other technologies exhibit significantly lower values, such as 60 for electrochromic systems and 120 for SPD technology. In terms of color neutrality, electrochromic technologies produce the least neutral results, whereas conventional blinds and MEMS smart glazing offer the best color neutrality.

Figure 5. Comparison of different window technologies existing for light modulation and light steering. The colors represent the fulfilment of the requirement by the technology for specific parameter. Green: good; black: medium; red: bad fulfilment.

Concerning speed, considering one window unit, which corresponds to 1.69 m2: For conventional blinds, a complete open-to-closed status change can require 10 s and an adjustment is finished after about 1 s, whereas MEMS smart glazing’s are much faster (< 0.1 s) and furthermore independent of temperature. All the other technologies show a strong dependence on temperature for their functionality. The slowest switching speed (1 h) is observed for electrochromic technologies at 0 °C and the fastest (0.1 s) for SPD at 20 °C, among other technologies. Thus, the MEMS technology triumphs in this field. Note that switching speed is considerably dependent on size. We also fabricated much smaller MEMS micromirror arrays and measured a fastest closing time of 1 µs.

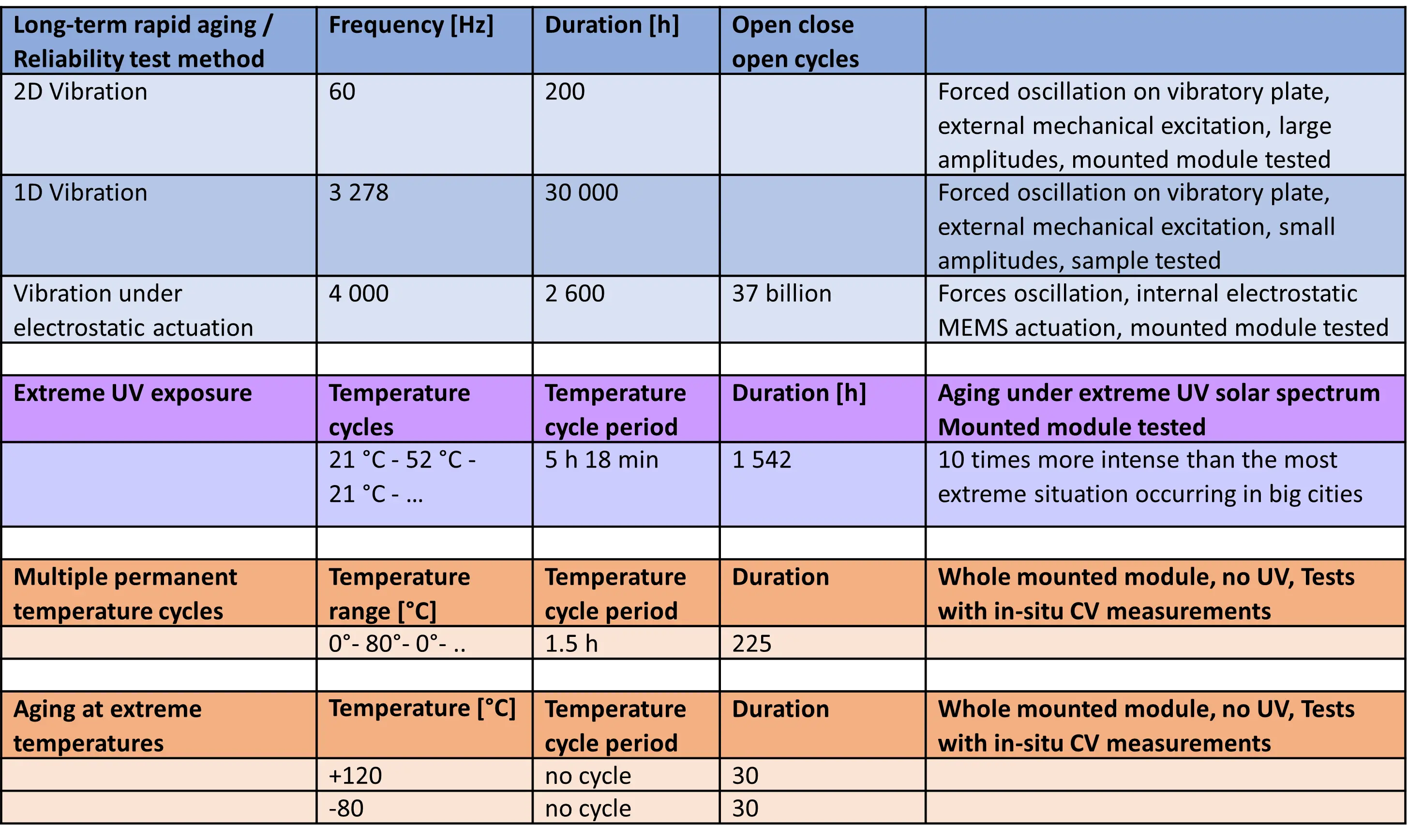

The shortest lifetime is exhibited by the exterior sunblinds while the longest is by the MEMS smart glazing resulting from the strong miniaturization of the mirrors.

The widest operating temperature range was measured for our MEMS micromirror glazing: ranging from low values of -80 °C up to 120 °C. It’s worth noting that we did not measure temperatures below -80 °C or above 120 °C due to the limitations of our equipment.

Electrochromic technologies, SPD, and PDLC are primarily optimized for summer rather than winter. As a result, their advantages are notably influenced by the season, making them highly season-dependent technologies. The functionality of our MEMS smart window is independent of season.

Conventional blinds have potential for light steering if the lamellae are completely flat and surface-coated with strongly reflective coatings like that of a bathroom mirror. Compared to the limited light-steering capabilities of other technologies, MEMS micromirror glazing stands out with significantly greater functionalities and a multitude of possibilities.

Technologies that rely partially or entirely on light absorption tend to convert the absorbed energy into heat. Consequently, a window equipped with such technologies can function as a radiant heater, which is particularly undesirable on hot summer days. Although these absorbing technologies effectively block near-infrared radiation (solar infrared), they re-emit it as mid-infrared radiation, depending on the temperature of the elements involved. In summary, undesired radiation heaters are avoided the most effectively in exterior blinds and MEMS smart glazing.

The energy consumption of a model day, defined as the energy needed for two full open-close-open cycles and 10 adjustments within a model day, is used to compare energy usage across various technologies. The energy consumption compared in Figure 5 is that for 12 actuations. The company WAREMA (selling external and internal blinds) gave us their exact motor powers and told us that in average per day the user is initiating two complete open-closed-open cycles and 10 adjustments of this mechanical blinds. However, a noticeable additional power consumption arises from holding a status in MEMS smart glass. In case of external and internal blinds, this does not apply. However, for all the smart glass systems this is a noticeable power consumption. There are reports for novel specific systems in a few cases, where publications report on no power consumption on holding (Section 5). Among these technologies, PDLC consumes the highest amount of energy (52 Wh/d), while our MEMS smart glazing records the lowest energy consumption (0.039 Wh/d). Considering much more activities, this results in a multiplication of the energy consumption by more or less the same factor. This means that the ratio between these different technologies remains approximatively the same. Scenarios of much more activities are considered in Section 2.3.

As previously highlighted, in the event of an abrupt power outage, both PDLC and SPD glazing have the potential to remain in an opaque state, posing a potential safety hazard due to the obstructed view from the outside during emergencies. In contrast, only MEMS smart glazing fully complies with all safety requirements in such situations.

When it comes to achieving a clear view through various technologies, electrochromic technologies currently offer the most favorable results.

In order to improve clear view through MEMS smart glass, our concept reduces diffraction effects by using as much as possible non-periodic micromirror shapes (irregular apertures) inside the arrays to reduce distortions and to provide a clearer view through the arrays. Theoretical studies using Fourier transform, as well as various optical transmission experiments, have been performed on different micromirror array designs. Arrays with irregular (non-periodic) and regular (periodic) have been compared for that purpose, using rectangular as well as trapezoidal apertures. Without any exception, all our experimental results have proven our hypothesis that non-periodic micromirror arrays are superior to periodic micromirror arrays. By varying geometrical dimensions of the apertures and the size of grating spacings, diffraction intensities of non-zero orders could be considerably suppressed[25,31]. On going efforts focus on enhancing clear view through MEMS smart glazing.

2.2 MEMS based smart glass

Next, this review provides an overview on MEMS solution for smart glass applications. Optical MEMS have been designed, fabricated and characterized for various light processing applications. Micromirror array-based MEMS have been presented for N × N switches in wavelength division multiplexing[32-34], for beamers[35,36], light steering via smart glazing for buildings[16,19,20,22-29,37] and adaptive optics[38,39]. Optical aberrations have been corrected in higher orders for applications in optical free space communication, astronomy, laser micromachining, maskless lithography and microscopic medical technology. Note that these MEMS mirror components are planar, and they are actuated electrostatically. Note also that some reflective adaptive optics exist reveal freeform shapes[40,41]. For switches and beamers[32-36], the mirror arrays are made of Si by MEMS standard processing and are planar. For light steering in smart glazing, the mirrors are metal based[27,37] and planarized using partial stress compensation.

Similar MEMS structure with metal-based but curled (rolled, i.e. non-planar) in their relaxed state, in contrast, are called microshutter arrays[42-47] or micro blinds[48]. Transmission modulation has been reported for these MEMS microshutter arrays for applications in smart glass[42,49], space instrumentation[43], camera shutters[45] and displays[46,49]. These MEMS microshutter arrays are curled in the open state (first state) and unrolled in the closed state by electrostatic actuation to reveal the flat condition (second state). These microshutter arrays reveal just two scenarios: completely open or completely closed. Pizzi et al.[46] developed curled microshutter arrays for car display applications. A similar system was reported using curled microshutter arrays[49], which are implemented between window planes for modulating sunlight entering rooms through windows or facades. In all these microshutter arrays, each shutter moves synchronously with the neighboring ones.

In contrast, our MEMS micromirror arrays enable active light steering for personalized lighting. Between the open and closed states, they allow several intermediate states. Light steering is possible since the mirrors are planarized and can be actuated into different tilt angle states.

Recently, Lamontagne et al.[50] published a laboriously reviewed article on microshutters, giving a valuable overview of that class of technology. That review also included our micromirror arrays. We have updated the tables of Lamontagne et al.[25], yet further update is made in this review to include recent values, as presented in Table 1. For our MEMS smart micromirror glazing, we measured a minimum transmissivity Tmin of 0.01% and, recently a maximum transmissivity Tmax of 77%, including the glass substrate with the TCO layer. This provides a modulation contrast of Tmax/Tmin= 7,700 between open and closed states. For a small sample of (3 × 4) cm2, we obtained a closing time as low as 1 µs in the centre.

| Research Group | Time period | Bottom Electrode | Top Electrode | Size | Actuation | Speed to Close | Demon. Size | TMax/TMin - Contrast | Applications, comments |

| Fiat[45,46] | 1999-2005 | ITO | flexible metal layer | 458 µm - 2.4 mm | 20-100 V | 0.1 ms | - | 2020/1/20 | Micro-shutter-based automotive display, IR spectrometry, low transmission |

| MCNC[51] | 2000-2002 | ITO | polyimide/Cr/Au/ polyimide | < 100 µm-> 200 µm | 100-300 V | 18 µs | 5 cm2 | Low contrast | eyelid for protection |

| Kassel University[16,19,20,22-29] | 2003-present | ITO, FTO or Ag low-e | SiO2-SiNx/Al-Cr-Al/Al-Cr-Al-Ge | (150 × 400) µm2 (100 × 1,000) µm² | 12-80 V | 1 µs | almost 1,000 cm² | 73/0.01-7,300 high contrast | sunlight steering for buildings, high contrast, low voltage |

| NRC[47,50] | 2005-present | SnO2, ITO, Ag low-e | Cr and others | 50 µm-300 µm2 | 15-25 V | 40 µs | 20 cm2 | 60/0.01-600 high contrast | high contrast, low voltage |

| NVMG[41,43] | 2007-present | TCO | shrinkable Polymer | ≤ 2 mm | 110-500 V | seconds | 5,000 cm2 | Low contrast | Macro-curling shutter, commercialized |

| INO[42,50] | 2008-2009 | Al | MoCr | (60 × 1,000) µm² | 110 V | 2 ms (7 ms to open) | 0.25 cm2 | Low contrast | Space instrumentation |

| Air Force[52] | 2008 | AlZnO | Ti and Au | (200 × 50) µm2 | - | - | - | 40/1-40 | Adaptive coded aperture imaging |

| Samsung[44,53] | 2009-2011 | ITO | Al-SiNx | Ø 2.2 mm, (36 × 1.4) mm2 long triangular rolled shutters | 30 V | 2 ms | Iris of 0.04 cm² | ? | Iris shutter for camera |

| KAIST[54,55] | 2010-2016 | ITO | Electroplated Ni | (200 × 160) µm2 | 20-30 V | 20 µs | Small | 60/? - ? | active transparent display with TR-OLEDs |

| University of Tokyo[49] | 2015-2016 | ITO | Al-SiO2 | (200 × 30) µm2 | 38-55 V | 3 ms | - | 53/36-1.5 | implemented on TFT |

| Stuttgart University[48,56] | 2016-present | MoTa | MoTa on stressed SiNx | 200 µm | 20-60 V | - | 2-225 cm2 | Low contrast | Transmissive display on TFT, low transmission |

MEMS: microelectromechanical systems. ITO: indium tin oxide; TR-OLEDs: Thermally Recombining Organic Light Emitting Diodes; FTO: fluorine-doped tin oxide; TCO: transparent conductive oxide; TFT: thin-film transistor.

The comparison of speed between different groups is not simple since it depends on sample size and the geometry of the metal grid including the metallic stripes. Recently, we performed theoretical model calculations including the electromechanical closing and the dynamic signal transport propagation for the potential built-up for that micromirror located furthest (maximum distance) away from the border of the array. For our FTO/SiO2/metal stack and the 3D strip-line geometry, we received a nonlinear dependence of the closing time versus stripe length. As a result, we assume that all the groups included in Table 1 (except NVGM) measured in small samples or close to the border. Both are almost identical for most of the groups since their samples were still rather small. NVGM most probably measured in the middle of their large sample. Our group is working towards 80 cm × 140 cm arrays, which is equivalent to more than 11,000 cm2. We hope to be able to report on the closing speed soon. Concerning switching times, our simulations provide the closing time as a function of the metal stripe length, allowing us to compare experimental results as a function of array size and stripe length. Photos of our MEMS smart glass having a size of 30 × 30 cm2 are shown in Figure 6.

Figure 6. Images of a (30 × 30) cm2 sample: (a) View through a MEMS micromirror array after fabrication; (b) Window module (double insulation glazing, argon, spacers, butyl sealing) with integrated MEMS micromirror array. The mirror status is partially closed. Contacts for subfield addressing are visible (2 × 2 subfields). MEMS: microelectromechanical systems.

Our MEMS micromirrors arrays reveal long lifetimes, high reliability, large operating temperature range and are season independent. The following rapid aging tests have been performed on our MEMS smart glass: multiple fast extreme temperature cycles, long-term UV aging at variable temperatures, shock tests and mechanical vibration treatments over 26,000 h, long-term actuation at 4 kHz i.e. close to the resonance frequency (7 kHz) over twenty billion cycles, and operation at extreme temperatures down to -80 °C and up to 120 °C. Surviving these different tests, successfully, also shows a longer and stable maintenance free lifespan.

A comparison of all the smart window technologies based on material, functionality and fabrication process is presented in Table 2. Reducing the cost per unit area for all smart glass technologies and scaling up the manufacturing process of our MEMS smart glass will be one of the major challenges. To achieve sustainability goals, it is imperative to enhance the lifetime (durability) of PDLC, SPD, and electrochromic technologies. Furthermore, additional enhancements in terms of contrast (modulation depth), color fidelity, and switching speed are expected. It is more likely that the limitations associated with passive systems such as thermochromics and photochromics, particularly in terms of tailored daylighting, cannot be improved. Additionally, the large-scale implementation of microstructured films can be hindered by challenges related to process stability and polymer shrinking. Certain companies offering passive light steering systems or passive sun protection technologies contend that the requirement of continuous electricity is a drawback for PDLC, SPD, electrochromic, and MEMS technologies. We do not share this opinion since active technologies are superior to passive technologies by far, thus, reveal much more chances for smart personal environments, smart homes and smart green cities. The urgent requirement to reduce the CO2 footprint associated with human activities will push governmental bodies to implement distinct measures aimed at reducing the environment in our society. We believe that this will create a favorable environment for the adoption and growth of active smart glass technologies[57-61].

| Type | Technology | Active/ Passive | Material | Fabrication Technology | |||||

| TCO | Active Material/Top Electrode | Dielectr. | Sacrifi. Layer | ||||||

| Sun shading system | Photochromics [57,58,62-64] | Passive | - | WO3, TiO2, V2O5, Nb2O5, MoO3 | Azobenzene, spiropyran, furylfulgide, and diarylethene | CVD, Magnetron sputtering, Sol-gel with dip-coating, PVD, Electron-beam evaporation, Ion-beam sputtering, pulsed laser deposition, Vapour-phase deposition (sputtering). Sol-gel and polymer assisted deposition | |||

| Thermochromics [59,64,65] | Passive | - | VO2, TiO2, Ni2+, Co2+, Cu2+, Fe2+ chelates based metal complexes | ||||||

| EC[60,64,66] | Active | ITO, AZO, ATO | WO3, TiO2, Nb2O5, V2O5, MoO3 | ||||||

| Gasochromics[61,66] | Active | - | WO3 | ||||||

| MEMS Micro-blind[25,50 | Active | SnO2, ITO, Ag low-e | Shrinkable polymer with Al, NiCr, Cr, SiO2/Al | Polymer, SiO2, SiNx, Al2O3 | Photo-resist | Si, | UV photolithography, PECVD, Optical laser patterning, wet and dry etching, Evaporation, magnetron sputtering | ||

| LC systems | Polymer-Dispersed Liquid Crystal[61,67] | Active | ITO | Nematic LC droplets into polymer | phase separation - (i) PIPS, (ii) SIPS and (iii) TIPS, encapsulation method | ||||

| Polymer-Stabilized Liquid Crystal[61,68,69] | Active | ITO | Monomer, polyimide | PIPS | |||||

| Suspended Particle Device[61] | Active | ITO | Dihydrocinchonidine bisulfite polyiodide | Lamination process | |||||

| Light directing system | Prismatic panels[70] | Passive | . | OrmoComp, PMMA | Hot embossing or injection molding, UV-nanoimprint | ||||

| Sine-wave structure[71,72] | Passive | . | PMMA | Thermal compression molding | |||||

| Laser-cut structures[73] | Passive | . | Acrylic pane | Melting and ablation via laser | |||||

| Microstructured films[74,75] | Passive | . | Acrylic pane on PET | UV-nanoimprint | |||||

| MEMS Micromirror arrays[16,19,20,22-29] | Active | ITO, ZnO, SnO2, AlZnO | Al/Cr/Al | SiO2 | Photo-resist | UV photolithography, PECVD, optical laser patterning, wet and dry etching, evaporation, magnetron sputtering | |||

TCO: Transparent conducting oxide; CVD: chemical vapor deposition; PVD: Physical Vapor Deposition; ITO: Indium Tin Oxide; AZO: Aluminum-doped Zinc Oxide; ATO: Antimony Tin Oxide; UV: Ultraviolet; PECVD: plasma-enhanced chemical vapor deposition; LC: liquid crystal; EC: electrochromics; PIPS: Positive Ion Probe Surface Spectroscopy; SIPS: Surface Ion Probe Spectroscopy; TIPS: Thermal Ionization Probe Spectroscopy.

2.3 Global impacts

Due to the prevalent energy inefficiency in the majority of building structures, the building sector offers the second most significant opportunity for energy savings, surpassed only by the energy sector itself. The urgent need to reduce CO2 emissions resulting from residential and commercial activities has spurred public attention towards taking distinct action in energy savings, which involves the adoption of energy-efficient technologies in new construction and the replacement of outdated and inefficient appliances in existing buildings. Initiatives such as the European Green Deal, which are focused on sustainability objectives like “Building and renovating in an energy and resource-efficient way”, lay particular emphasis on the building and construction sector and addressing the imperative of renovating both public and private building stock to incorporate energetically efficient and resource-conscious housing solutions. Integrating digital technologies and climate-proofing tools is necessary to enhance overall performance. Furthermore, emerging technologies must guarantee essential energy services to ensure a basic standard of living for all citizens at an affordable cost, thereby combatting energy poverty. These principles align with the objectives outlined in the New EU Directives on Energy Performance of Buildings (2018), which aim to achieve a low and zero-emission building inventory in the EU by 2050. This ambitious goal is boosted by the integration of smart technologies. Another core sustainability objective of the European Green Deal is the implementation of a zero-pollution ambition and creating a toxic-free environment. The substantial reduction in energy consumption within buildings will certainly result in a decrease in greenhouse gas emissions.

Smart window technologies, despite their limitations and drawbacks, have the potential to deliver substantial energy savings by harnessing daylight and solar heat. Sun shading window technologies, for instance, can result in energy savings of approximately 22% compared to standard double-glazed windows[15]. Our MEMS smart window, specifically, has the capacity for significant energy conservation, amounting to a remarkable 2,240 TWh in the EU alone. This translates to a reduction of 339 Mt of CO2 emissions[16]. The urgency to mitigate CO2 emissions, coupled with the promise of these emerging technologies, will drive the advancement of surface technologies, particularly in the scope of smart glass.

2.4 Current and future market trends

The continuous rise in energy consumption, driven by extensive demands across various sectors, particularly in the building sector, accounts for approximately 50% of final energy consumption and contributes to 33% of greenhouse gas emissions. The European Commission (EC) has reported that a significant number of buildings were constructed prior to the first thermal regulations in 1970, rendering them energy-inefficient. Furthermore, as of 2020, existing buildings already make up 70% of the building stock that will be present in 2050.

Research has revealed[9] that around 70% of the buildings in the European Union are more than 30 years old, with 35% exceeding the 50-year mark. Considering these unavoidable circumstances and the positive public reception of energy-efficient household appliances, as demonstrated in numerous studies, implementing energy-efficient retrofit has yielded mixed results due to the high initial investment and a slow turnover rate. However, smart window technologies, particularly our micromirror array-based windows, are regarded as one of the most promising solutions that can be applied to existing buildings. This is attributed to their lower acquisition cost and high potential for energy savings.

As per various business analytics reports, the Global Smart Glass Market is projected to reach a value of $14.05 billion by 2032[76], demonstrating a robust CAGR of 10.8% (2023-2032)[76]. This growth is primarily fueled by escalating political pressures promoting building renovations and the incorporation of smart green building and city concepts. These factors are expected to boost our product sale in both new and existing building stocks. Furthermore, there is a growing preference for technical energy-saving measures, such as house insulation and energy-efficient products, over strategies that involve minimizing resource usage. Consequently, the adoption of smart glass in building applications is expected to experience accelerated growth in the coming years. Smart glass is assessed to capture a significant share of the future window market, driving substantial advancements in surface technologies.

The intelligent control of light, room temperature, and humidity is set to become a central focus in the development of future building technologies. This approach aims to mitigate heat losses, harness solar heat, and provide occupants with natural lighting, which has a positively impacts on human health, happiness, and overall well-being.

3. Simulation of Light Steering Inside a Model Room Using MEMS Micromirror Smart Glass

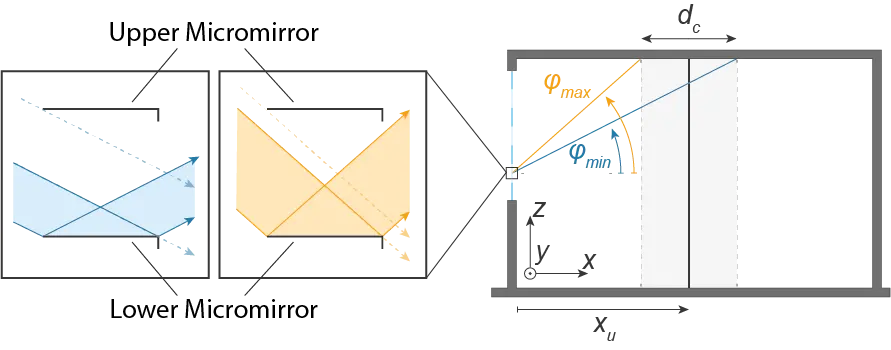

The lighting situation within a room is composed of natural and artificial lighting in certain proportions, depending on individual brightness requirements. Regarding sustainable and energy-efficient building design, the use of available natural solar resources is becoming increasingly important[77]. In order to investigate daylight-steering via MEMS micromirror arrays, we already used analytical calculations and ray tracing simulations back in 2015[78]. The focus of that work was, among others, the development of an analytical model for the computationally efficient simulation of daylight deflection of 1D micromirror arrays. Beyond these investigations we improved the ray tracing simulations, considerably regarding flexible user positions combined with the correlation of the distinct addressed light spot sizes at the ceiling above the users and the angular distributions of the brightest areas in the sky. Since the micromirrors are divided into subfields that can be controlled independently of each other and tilted at different angles, an optimum personalized and individual lighting situation can be achieved[23,79]. Within this article, we will present the methodology for determining the required angular positions of the micromirrors for all subfields, the creation of the simulation models and point-in-time simulations in a model room to investigate the amount of light that can be achieved by light steering quantitatively. Our considered scenario comprises a model room with four windows (137.9 × 81.3) cm2, a vertical wall part of 77.1 cm (above) and 85 cm (below), respectively, a room height H = 3 m, a room width W = 4.5 m and a room depth D = 8.3 m (Figure 7). The window is south oriented, and we consider noon daytime on June 21st. For simplicity, only 1D actuation is considered. Note that via adequate 2D light steering, other window orientations and other day- and season-times can also be easily put into consideration.

Figure 7. Geometry of the model room with a visualization of the light cone, further notations, and reflection and transmission behavior through the micromirror array smart glass. Reproduced with permission from[28].

3.1 Angular position determination

An efficient use of our MEMS micromirror smart glass as a light steering system requires an adequate control system that automatically optimizes the lighting situation depending on the actual environmental parameters at that particular moment. Both indoor and outdoor conditions must be considered for the control process. For optimum control, a compromise must be made between the maximum possible illumination (to save artificial lighting) and simultaneous minimum heating (to save air conditioning) of the room. A crucial factor for this trade-off is the information about the presence of people in the room, since only in this case it is necessary to prioritize the lighting of the room. If no users are present in the room keeping the room cold will be prioritized in hot summer days, whereas harvesting as much as possible solar radiation and heat will be prioritized in winter. In the following, the procedure for determining the mirror angles will be presented, focusing on optical optimizations without reporting the involved additional thermal influences.

Since the micromirror arrays are a light steering system, the user benefits from the resulting diffuse scattering of light from the ceiling, which is initially redirected by the micromirrors to the room ceiling above the user. To perform such controlled light steering, the first step is to detect the position xu of the users in the room. In the general case, i.e., 2D light steering, the x- and y-coordinates of the people in the room are recorded. In the 1D case, considered here for simplicity, the determination via the x-coordinate is sufficient since the light deflection (ray tracing) mainly varies in the xz-plane. According to Figure 7, the detected x-coordinate of the user position xu is the target position of the center of the “light cone”, which is spanning the distance dc at the ceiling. The smart glass with the micromirror arrays includes multiple subfields, which are arranged in rows and columns, where the mirrors in each subfield, are tilted identically. For each subfield, the relative position to the projected light cone varies in z-direction. As a result, an individual angular configuration must be calculated for each subfield. Due to the borders of the projected light cone, an individual acceptance angle pair φmin and φmax can be derived for each subfield, under which the incident light contributes to the angular intensity profile inside the light cone. Thus, the objective is to align the micromirrors so that the luminance is maximized for the incident light angles within the spanned distance dc. For this purpose, it is necessary to determine those angles of incidence of the sky from which the highest luminance emanates (brightest areas in the sky, in short). In addition, the angle-dependent transmission and reflection properties of the micromirror array must be considered since only those angles originating from sky regions with high luminance can effectively contribute to light cone formations. In order to systematically perform this optimum angle search (for the 1D steerable micromirrors), a two-step ray-tracing script was written to determine the angle-dependent transmission properties of the micromirror array by brute-force search. This is performed for all feasible angular positions, first in the forward and then in the backward direction. Based on the obtained results, the optimum angular mirror tilt of a subarray is determined, in consideration of the existing angle-dependent luminance in the sky. These serve as input parameters for the daylight ray tracing simulations described later to show the potential of light steering based on three lighting scenarios. Note that the sky’s brightness varies abruptly in case of direct sun incidence or sharply bordering white clouds. However, during overcast days the brightness can vary softly, providing no sharp cone borders. Soft borders of the light spot at the ceiling are desired and will additionally appear by very small deviations from 100% planar mirrors (minor curling or mirror surface roughness).

3.2 Complex fenestration system (CFS) modelling

A complex fenestration system implements advanced window architecture, applying special technologies. Such a system aims to optimize light conditions in a room by means of light shading, guiding and redirection, refraction or even further phenomena[80]. The characterization and physical modelling of complex fenestration systems can be difficult and vary in procedure from case to case[81,82]. The optical transmission characteristics, based on the angle-dependent transmission and reflection behavior, can be described using a so-called bi-directional scattering distribution function (BSDF)[83]. A BSDF in the field of daylighting simulations represents a data-based and discretized function of the visible and solar reflectance and transmission properties of a window system that can be used in terms of simulations. The determination of that BSDF can be performed physically by the angle-dependent measurements of a real sample using a photogoniometer or virtually based on a ray tracing method using the modelled geometry of the CFS and its materials[81,82]. Since no complete measurement data for the physical modelling of the BSDF of the described micromirrors are available so far, a BSDF generated via ray tracing is used in the context of this work. For this purpose, the validated light simulation software Radiance[84] is used, which generates a BSDF with a user defined resolution as a low-resolution Klems BSDF or high-resolution Tensor Tree BSDF using the genBSDF tool that is included in Radiance. For the following workflow, both Klems and Tensor Tree BSDFs are used. To create the models considering thermal behaviour, Klems BSDFs with an angular resolution of 13.5° are used (according to the 145 × 145 subdivisions per incoming and outgoing hemisphere) since a high angular resolution is not necessary for these simulations. However, for the optical simulations, Tensor Tree BSDFs with an angular resolution of 2.53° (according to the 4,096 × 4,096 subdivisions per incoming and outgoing hemisphere) are used to represent the high specular reflection effects of the micromirrors during light steering in reasonable accuracy[85]. Even though it is possible to create Tensor Tree BSDFs with much higher angular resolution, they require substantial computational effort, so the chosen angular resolution is a compromise between acceptable computational time and sufficient accuracy according to the dimensions of the model room. For the generation process of the BSDFs, a 3D CAD model of the system to be characterized is required. This model is created using the computer-aided design software Rhinoceros[86] and the plugin Grasshopper[87] for parametric modelling. To investigate the influence of different angular positions of the micromirrors on the simulations, it is necessary to model a corresponding geometry for each angular configuration under investigation. For this purpose, models are created for all tilt angles Φ of the respective subfields required to create a light cone at user position xu (Table 3).

| Smart Glass Subfield | |||||||

| xu | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 2 m | 20° | 17° | 15° | 13° | 11° | 10° | 8° |

| 4 m | 25° | 24° | 22° | 21° | 20° | 19° | 18° |

| 6 m | 27° | 26° | 25° | 25° | 24° | 23° | 22° |

Subfield 1 is the topmost and 7 is the lowest subfield in the z-direction.

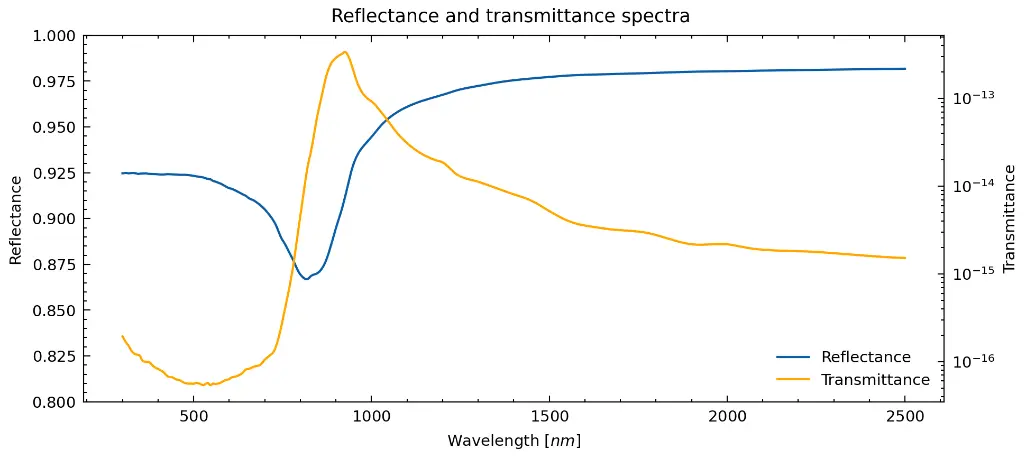

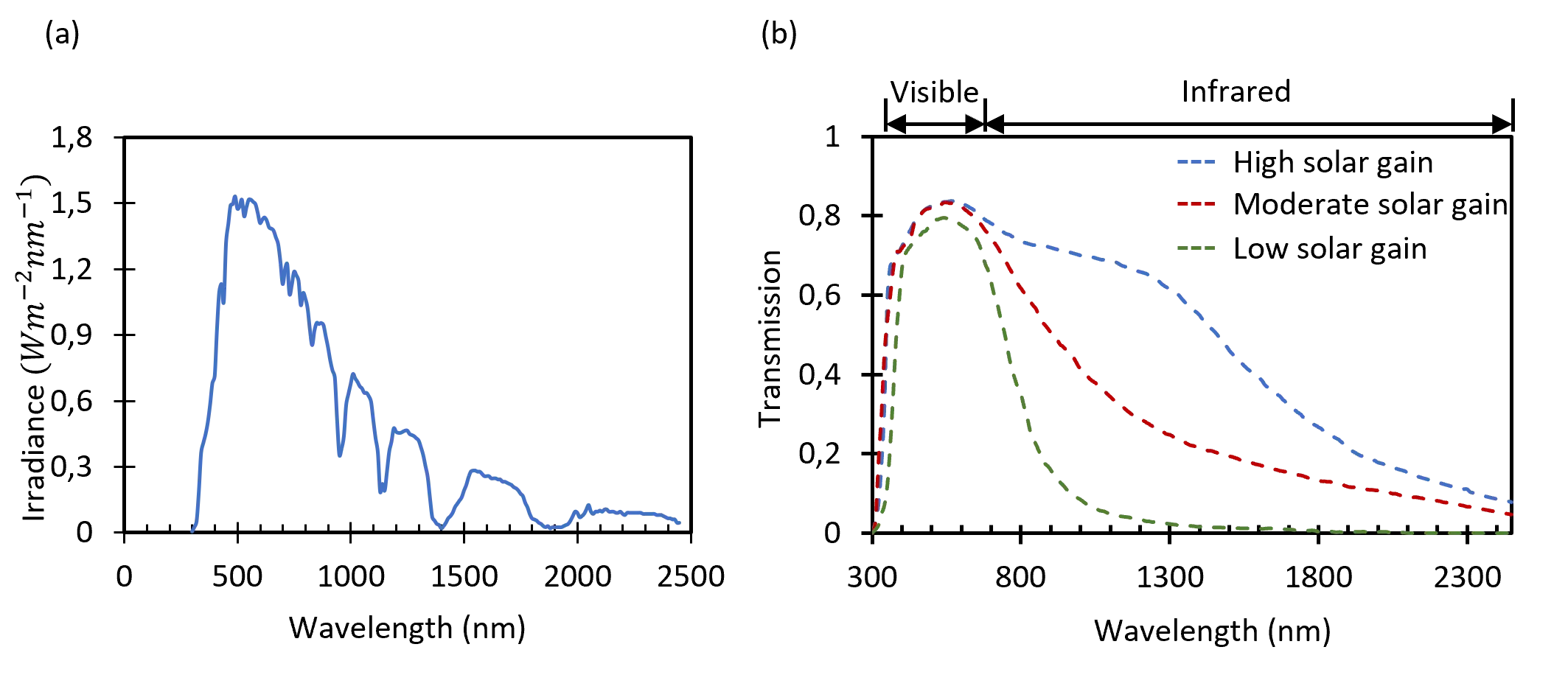

Since the angular resolution of the Tensor Tree BSDFs used is limited to 2.53°, this implies that the results may deviate slightly from the achievable optimum. However, they should be sufficiently accurate to show the achievable effects in the model room. Since both optical and thermal simulation model of the micromirror array has to be created, which can describe the behavior over the relevant wavelength range from 400 nm to 2,500 nm of the electromagnetic spectrum, the geometrical models additionally require an assignment of realistic material properties of the micromirror array. For this purpose, the reflection and transmission spectra of the micromirror metallic stack are determined via the open-source software OpenFilters[88] by modelling the multilayer system of the micromirrors to obtain the required values for the material assignment. As expected, the transmission spectrum of the metals is nearly zero over the considered wavelength range, as shown in Figure 8. The reflection shows a profile that is characteristic of aluminum. Subsequently, the colorimetric properties of the metallic layer system for a correct color rendering of the reflected light are determined by standardized colorimetric methods using the CIE standard illuminant D65, the CIE standard observer CIE-1931 and the reflection spectrum of the layer system using OpenFilters. The calculated L*a*b* color values can be converted to equivalent RGB color values that can be processed by Radiance. For the sake of simplicity, the layers of FTO and silicon dioxide are neglected in the description of the material properties. The specularity and roughness values were assumed to be optimum according to the high-quality technological processes used to fabricate the layers.

Figure 8. Simulated reflectance and transmittance spectra of the modelled metallic multilayer system. Reproduced with permission from[28].

Based on the considered geometries and its material definition, genBSDF is used to generate both a low-resolution Klems BSDF and a high-resolution Tensor Tree BSDF that can be used to describe the visible and infrared reflection and transmission properties of the micromirror array. Since the Tensor Tree BSDFs are generated for the micromirror element combined with the glazing using genBSDF, the Klems BSDFs, however, are generated only for the micromirror element without the glazing. Therefore, the generation of the Klems BSDFs of the entire CFS is done using the open-source software WINDOW 7.7 from Lawrence Berkeley National Laboratory[89]. In this process, a glass system is added to the already generated Klems BSDFs that represents the micromirror system and the thermal material properties are added beforehand. These include the thermal conductivity of the materials, the thermal emissivity of the front and back sides of the metallic micromirrors, and the thermal infrared transmissivity Tir (Table 4).

| Parameter | Value |

| Thermal conductivity [W/m × K] | 237.0 |

| Thermal emissivity, front [%] | 0.00019 |

| Thermal emissivity, back [%] | 0.00019 |

| Infrared transmission Tir [%] | 1.27•10-13 |

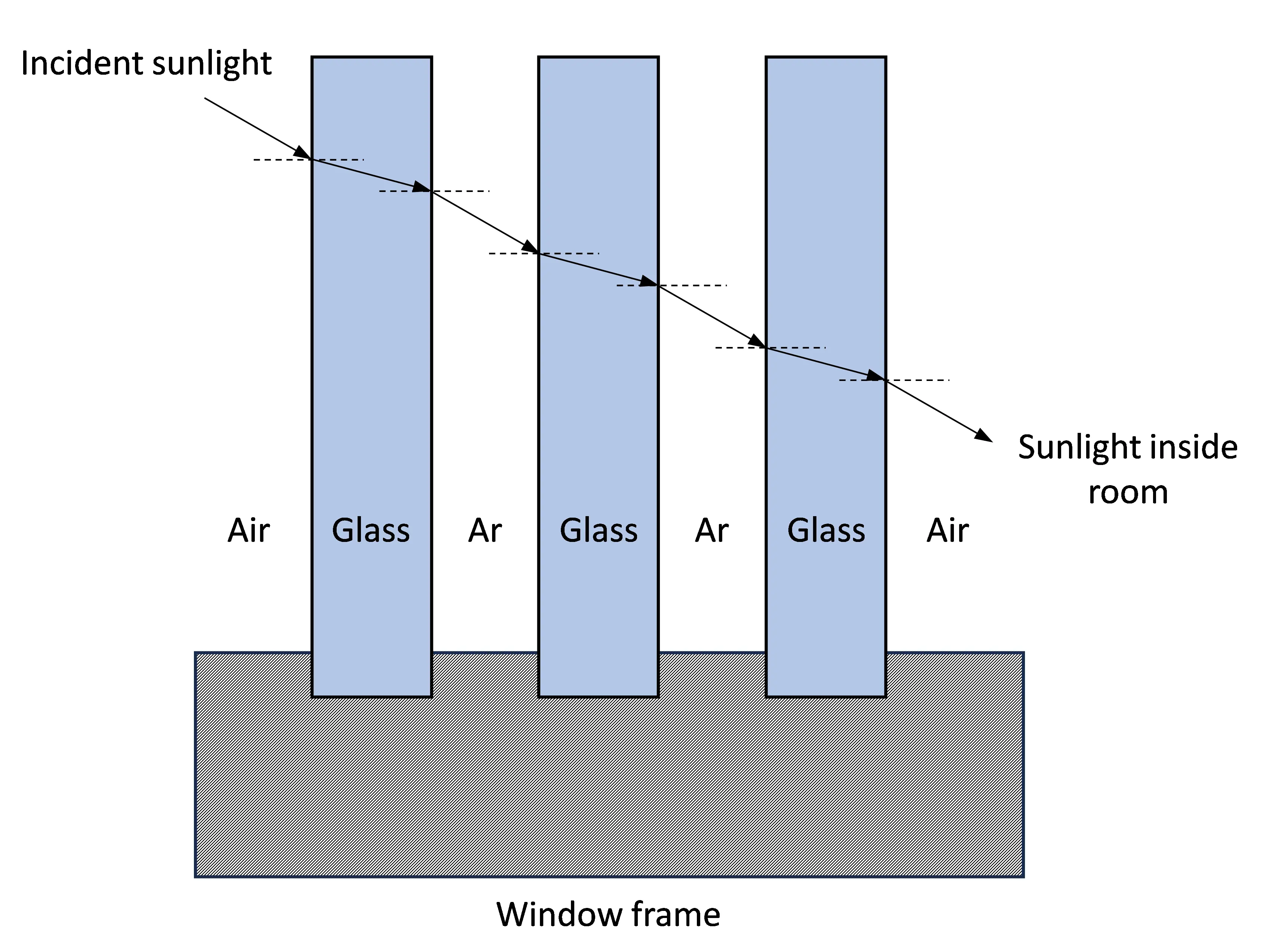

The value for Tir was determined as an average value based on the transmission spectrum of the aforementioned layer system created with OpenFilters over the wavelength range from 750 nm to 2,500 nm, while the values for the thermal conductivity and the thermal emissivity were taken from literature[90,91]. Although only daylight simulations are considered below, a model with thermal material properties is created since the thermal transmittance (Ug-factor) and solar heat gain coefficient (g-value) of the window model can be calculated within WINDOW 7.7 next to the visible transmittance (Tvis), so that these can be used with regard to future thermal simulations. While Tvis and g-value are calculated integratively over all outgoing light angles for incoming light at normal incidence, the Ug-factor is determined based on ISO 15099 defined calculation standard for shading devices[92]. The fenestration system, in which the micromirror array is to be integrated, is a quadruple glazing (QG), as shown in Figure 9 with the properties mentioned in Table 5 and corresponds to that of the demonstrator described[19,20]. QG was chosen due to the current trend towards insulation glazing with a higher number of panes. Additionally, the stronger ray spreading in QG increases the complexity of the simulation and makes direct transfer of the results from double to QG inadequate. The thickness of the micromirror material is negligible (maximum extension is 150 μm in the x-direction) in comparison to that of glass and argon filled gap, thus, ignored in the calculation. To exclusively consider the influence of the micromirror array on the improvement of the CFS properties, the integration of a low-e coating within the glazing structure is omitted. Due to the high sensitivity of the micromirror arrays to moisture, the inert gas atmosphere used in the interpane cavity is 100% argon due to its low heat conduction (monoatomic gas has minimum degrees of freedom). Table 6 shows the previously mentioned properties for quadruple glazing as a reference and for a glazing system with micromirrors for completely open (0°) and closed (90°) tilt angles, as well as averaged values for all other tilt angles used between 1° and 30° for the sake of simplicity, since these show only slight deviations. When considering Tvis exclusively through the quadruple glazing, about 65% of the incident light is transmitted through the glass. On the other hand, integration of micromirror array will result in additional transmission losses of about 5-10% due to the micromirror structure, depending on the tilt angle. Even though the quadruple glazing already provides an efficient insulation performance with a Ug-factor of 1.16, this property can be even improved further by almost 35% through the integration of the micromirror arrays by achieving a Ug-factor of 0.76. Likewise, compared to the reference glazing, the g-value can be improved by 7-12% depending on the tilt angle up to 30° and even by 86% to a g-value of almost 0 for the complete closing of the micromirrors. This shows that by modulating the g-value through the opening and closing of individual subfields, it is possible to control the occurrence of solar emitted infrared radiation in order to specifically adjust the heating of the room.

Figure 9. Glazing structure of the CFS with micromirrors (the left side faces the outside; the right side faces the inside of the room). Reproduced with permission from[28]. CFS: complex fenestration system.

| Layer | d [mm] | |

| 1 | Generic clear glass | 3.912 |

| 2 | Pure argon | 16 |

| 3 | Micromirror structure | - |

CFS: complex fenestration system.

| Tvis | Ug-factor | g-value | |

| QG | 0.65 | 1.16 | 0.59 |

| 0° | 0.60 | 0.76 | 0.55 |

| 1°-30° | 0.55 | 0.76 | 0.52 |

| 90° | 0.00 | 0.76 | 0.08 |

CFS: complex fenestration system.

3.3 Daylight ray tracing simulations

The potential for the yield of daylight that can be achieved with the help of our micromirror smart glass will be introduced in the following using the example of a model room under consideration of different user positions in room depth (x-direction) as target position in light steering. The modelling of the room is also performed with Rhinoceros and Grasshopper. The daylight simulations are performed within the modelling environment of Rhinoceros and Grasshopper using the plug-in Ladybug Tools 1.5.0 (contains Honeybee for daylight simulations). Ladybug Tools[93] is a simulation environment that provides comprehensive building simulation based on various validated simulation engines (Radiance, EnergyPlus, OpenStudio, etc.). To investigate the modelled CFS, the window apertures of the room model are assigned with the previously generated BSDFs, as well as with a reference glazing based on the identical glass system. The daylight simulations performed in Honeybee as a part of this work are also based on Radiance, so appropriate simulation parameters must be chosen to perform the simulations.

The simulations’ design performed is based on a 4.5 m × 8.3 m × 3 m model room (further properties are listed in Table 7). The orientation of the installed windows is chosen in geographic south orientation. The location of the model room for performing the simulations is at a mid-latitude in Europe in the center of Germany (Kassel, 51°19′0′′N, 9°30′0″E).

| Parameter | Detail |

| Room size | Width: 4.5 m; Depth: 8.3 m; Height: 3.0 m |

| Window orientation | South |

| Surface diffuse reflectance | Ceiling: 80 %; Wall: 50 %; Floor: 20 % |

| Grid height | Work plane: 0.85 m |

| Ceiling: 3.00 m |

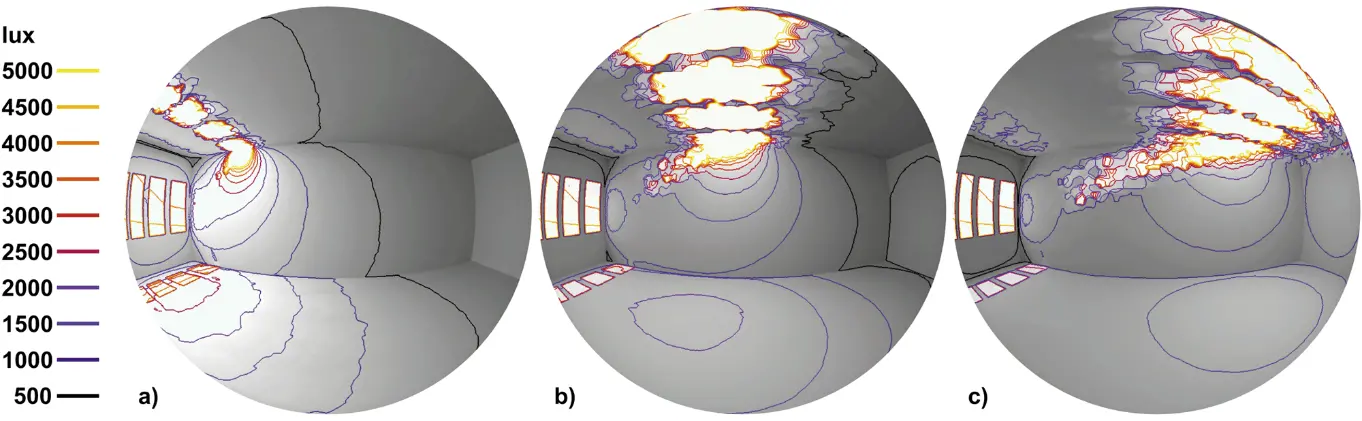

The strength of the micromirror based smart glass lies - next to the improvement of the Ug-factor and modulation of the g-value of a window glazing - in its dynamic control of daylighting, allowing it to be directed to a desired position in the room. A point-in-time simulation is performed based on a CIE standard clear sky to simulate this behavior. The simulation time is June 21st at 12 noon in the previously described model room. According to the sun’s position at a considered daytime, the angles with the highest luminance are at altitude of 61.8° and azimuth of 168.3°. Following the calculation procedure described above, the optimum angle configurations for three different lighting scenarios are derived and shown in Table 3. Those three simulated scenarios vary with respect to the user’s position xu = 2 m, 4 m or 6 m. At that position the user is illuminated via a light spot location xu at the ceiling. To check the lighting situation generated, the illuminance on the work surface and ceiling is shown as a function of the horizontal x-coordinate directed into the depth of the room, respectively as shown in Figure 10.

Figure 10. Illumination distribution due to light steering by our micromirror smart glass for a user position xu = 2 m, 4 m and 6 m and by the reference glazing (QG) without micromirrors. Note that the work plane is 85 cm above the room floor. Reproduced with permission from[28]. QG: quadruple glazing.

This figure displays the illumination distributions on both the work plane and the ceiling, with and without micromirror smart glass inside a QG. The shift of the brightness maxima at the room ceiling, caused by the shift of the user’s position xu, can be clearly seen from the illumination of the work surface by means of diffuse scattering. It is particularly noticeable that the brightness maximum of almost 30,000 lx on the work surface is directly at the window when the glazing without micromirrors is used. With the use of micromirrors, on the other hand, this unused light is steered onto the room ceiling so that the diffuse reflection of the light cones in all three cases provides an illuminance of at least 2,000 lx to 3,000 lx on the work surface below the light cones. For the case xu = 6 m, the illuminance does not fall below 1,000 lx even over the entire length of the room. Since the tilt angles of the micromirrors were calculated exactly for the x-coordinates mentioned for the different scenarios, a slight deviation between the light cone maxima and the intended target position can be seen, which is in the range of 20-30 cm. These deviations can be caused both by the fact that the angular resolution of the Tensor Tree BSDFs is not optimum, thus the required angles cannot be resolved sufficiently; and that the calculation of the required tilt angles is limited to integer values, which always results in a slight deviation that is especially noticeable at higher room depths. For a more descriptive 3D consideration of the model room under the three different lighting scenarios, these are visualized in Figure 11 as rendered images with an indication of the locally existing brightness distributions. Based on the brightness contour lines within the room, the influence of the controllable light cones on the entire room can be assessed more clearly. Since the sun is not exactly in the south direction (latitude 180°) at the observed time at the location carried out with latitude 168.29°, this can be recognized by the slight extension of the light cone on the wall which is in the background in Figure 11. This is a lateral displacement that cannot be compensated with the 1D tilt angle, which consequently validates the necessity of the previously presented 2D actuatable micromirrors to guarantee optimized control for arbitrary sun positions. Further improvement of flexible daylight steering including 2D actuation will be part of future work and will reveal greater potential of our MEMS micromirror smart glass technology, allowing active light steering independent of the window orientation, the season, the daytime, and the user movements.

Figure 11. Rendered images in fish eye lens perspective from inside the model room to view the overall impression of the illumination distribution considering the generated light cones at xu = 2 m (a), 4 m (b) and 6 m (c). Reproduced with permission from[28].

Different user actions require adequate illuminance. Bureau working places, including writing and data processing require 500 lx. If technical drawings by hand are included, 750 lx is the minimum requirement. As for the workshop and working place of opticians, 1,500 lx is prescribed. However, if the room usage simply involves walking inside the room, less than 500 lx is sufficient. For example, warehouses should be illuminated with 100 lux. This is sufficient to orient oneself, to find stored goods quickly and safely, and to make them available quickly if necessary. The standard also stipulates that, e.g., 300 lx should be achieved in shipping.

This means we are by far above the required illuminance in many use cases as per the result in Figure 10. By using less subfields, we can locally reach the required light conditions by far and save more energy, for example in summer. We will focus on this field in our future work, and we will also integrate 2D actuation in our simulations.

Furthermore, a completely homogeneous ceiling illumination is possible, using adequate cooperation of all the subfields in daylight steering via our smart glass. This is a very attractive scenario in winter, e.g., when we wish to harvest the whole available visible, near and mid infrared solar radiation, in order to save energy for heating. Note that visible and near-infrared (solar infrared) is converted into heat (mid infrared) after the electromagnetic radiation has been absorbed by any objects inside the room. In summary, a challenging and interesting working field lies ahead.

4. Energy Saving and Amortization Times

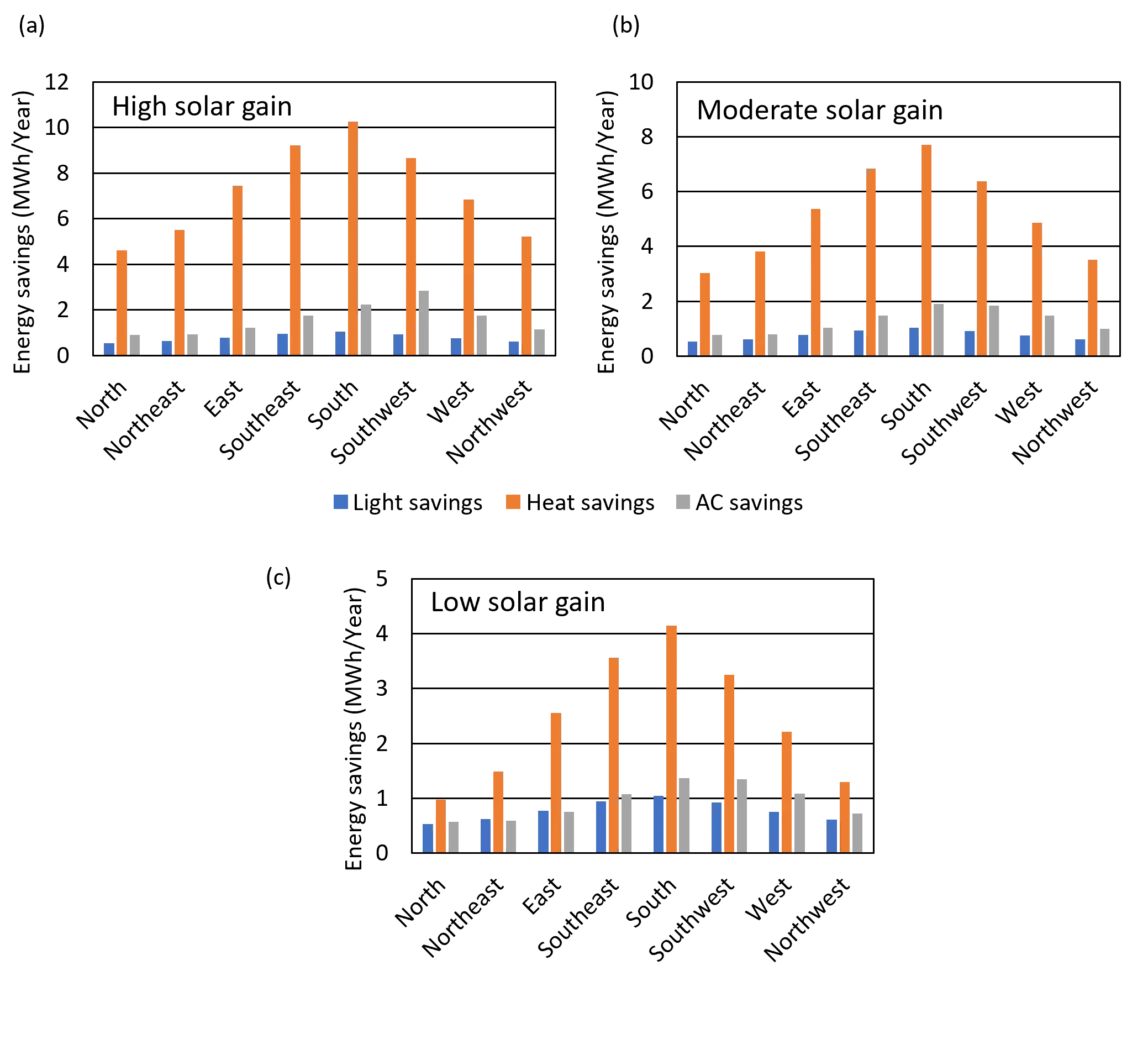

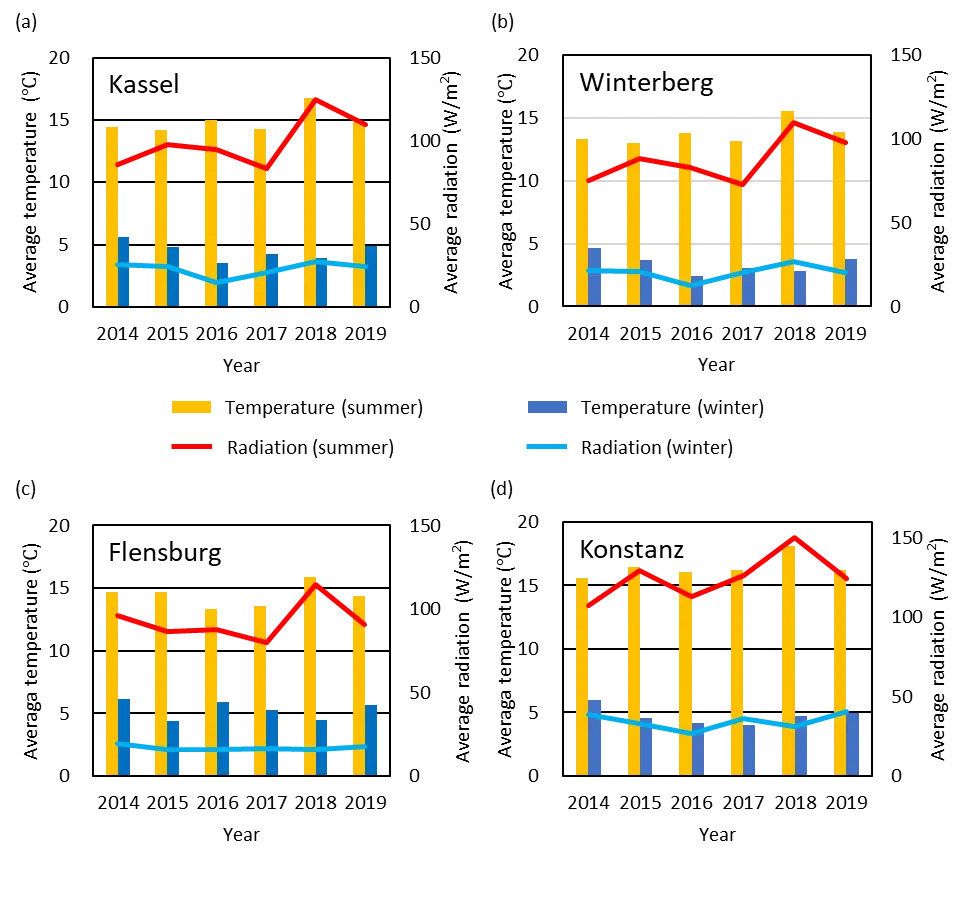

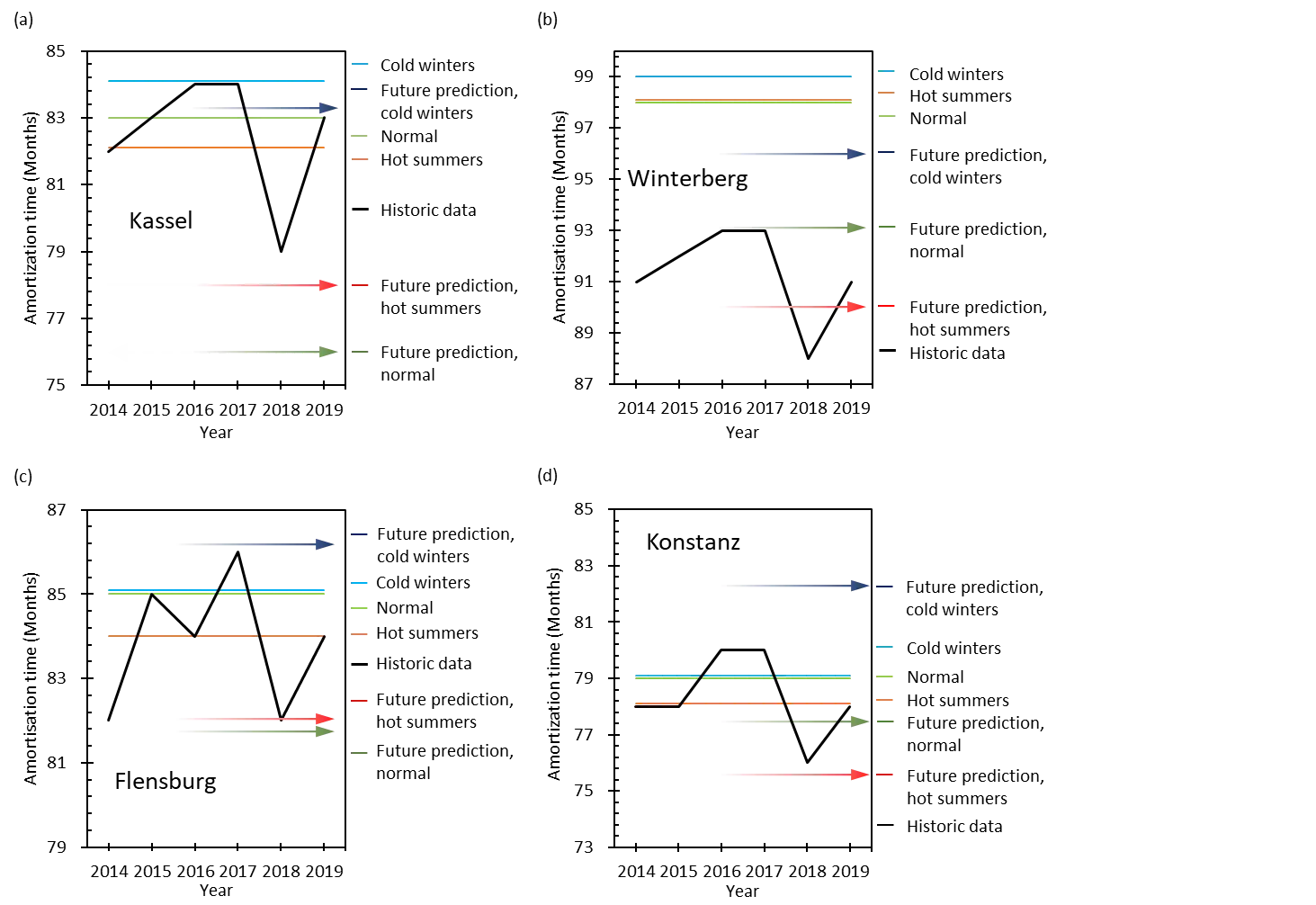

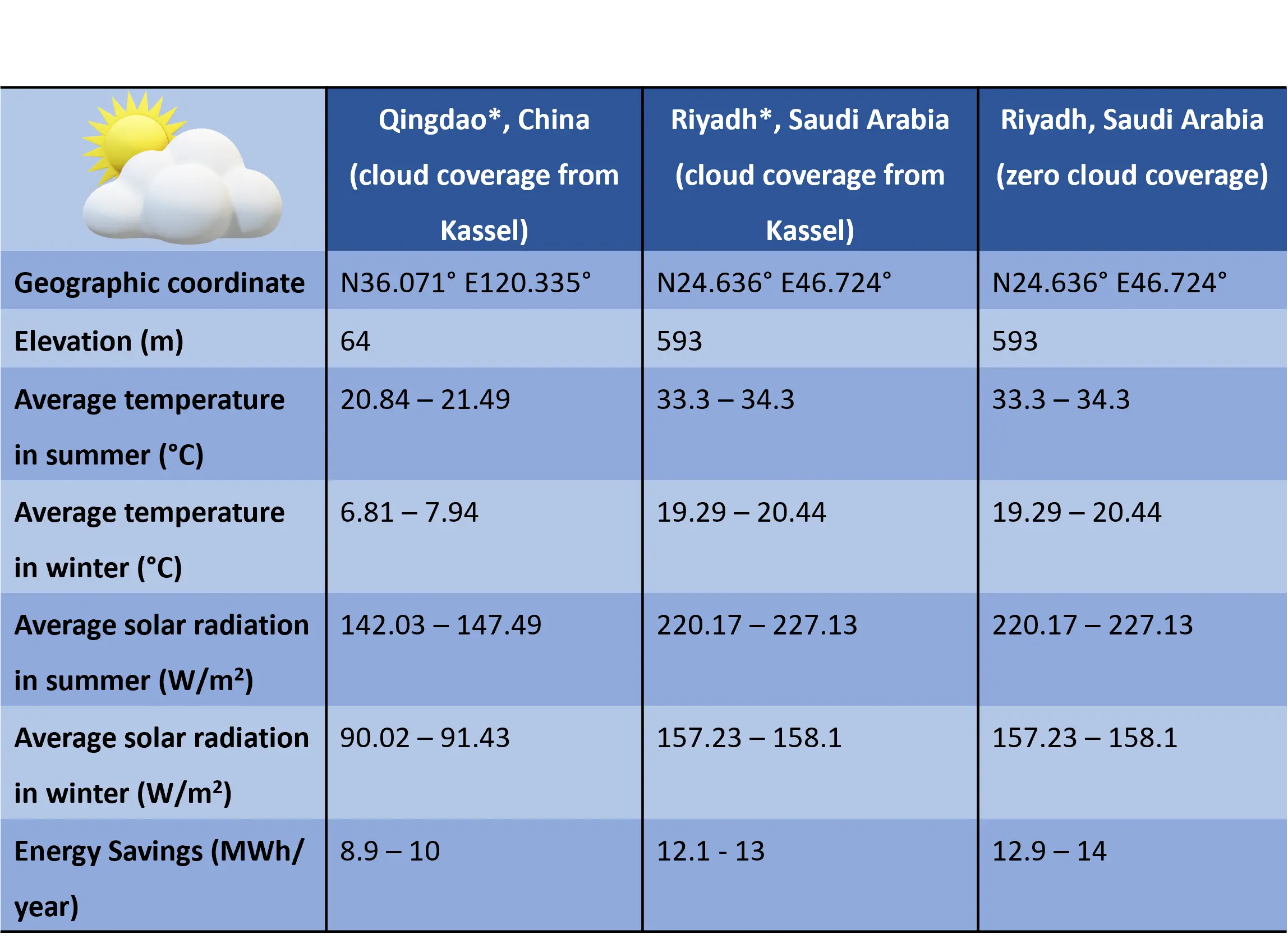

The energy savings and amortization time simulation is carried out in two steps depending on the weather database, electricity price and engine class reduction for MEMS smart window in comparison to a window with conventional tiltable aluminum blinds. Firstly, comparatively lower electricity prices and constant engine class reduction are used along with the Test Reference Year (TRY) database generated from the observation of previous years for Kassel, and secondly, the simulation is conducted for four different cities in Germany (Konstanz, Winterberg, Kassel and Flensburg) considering an increased electricity and equipment price, varied engine class reduction, actual and future predicted TRY database. A comparison of the amortization is made in relation to the available historical data (2014-2019) and future predicted TRY data. Furthermore, the simulation extends to two cities outside of Germany, namely Qingdao, China, and Riyadh, Saudi Arabia, using historical data covering the period from 2014 to 2019.

4.1 Energy savings and amortization time calculation for Kassel, Germany

4.1.1 Room scenario and investment

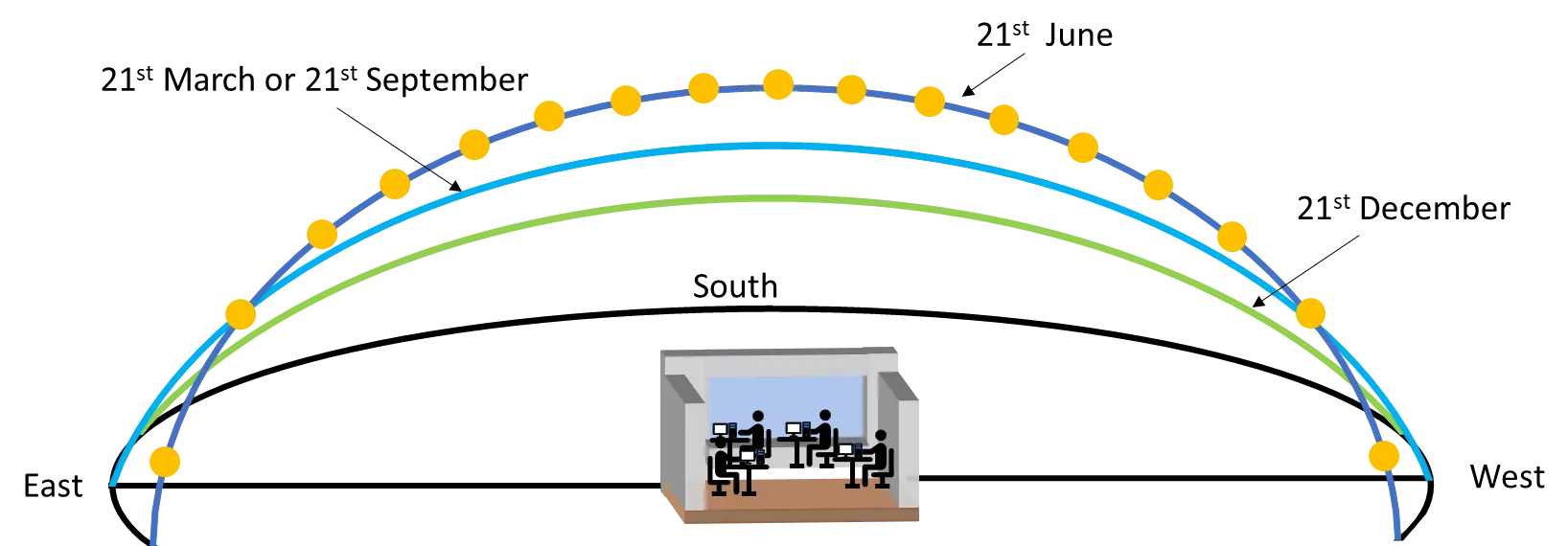

Maximum utilization of sunlight and limiting the requirements of space heating, air conditioning and artificial lighting that leads to energy saving is the principal aim of micromirror-array-based smart windows. Consequently, window orientation plays a crucial role depends on the location and sun’s position in the sky during the course of the day in different seasons. In order to face the sun and utilize the maximum solar radiation, windows must be south-oriented in the northern hemisphere, or the opposite in the case of the southern hemisphere. The sun position throughout the day in winter, summer, spring and fall for the stated room condition is illustrated in Figure 12. During summer, the sun rises in the northeast and sets in the northwest, following a high and lengthy path in the sky at solar noon during the summer solstice. Furthermore, the northern hemisphere tilts towards the sun in the summer, resulting in extended daylight hours and intense heating from the sun’s overhead position. In contrast, during winter, the sun rises in the southeast and sets in the southwest, following a shorter trajectory and reaching a relatively lower point in the sky at noon. During the winter solstice, the hemisphere tilts away from the sun, resulting in shorter daytime hours and colder weather. The sun’s path remains in between these two stated extreme positions during other times of the year.

Figure 12. The sun’s path with respect to an office room located in the northern hemisphere for winter, summer and spring and fall. Reproduced with permission from[16].

An office room with dimensions of 12 m length, 8.3 m width and 3 m height on the sixth floor of a commercial building in Kassel, equipped with a triple insulation windowpane having dimensions of 12 m length and 3 m height, covering the whole area of a south facing wall, is considered. The office room is occupied by 20 persons and furnished with 10 tables, 20 chairs, 20 computers, 20 mobile phones and 10 cupboards. It is important to note that in the model calculations, the occupants perform identical activities throughout the working hours all over the year. The manufacturing and installation cost of a 36 m2 normal window as well as the operating cost of micromirror arrays (module including manufacturing and installation) and window with aluminum blinds (including motor, controller, adapter and interfaces) are considered in the calculation. The maximum energy saving we would obtain comparing windows without any blinds and with windows having MEMS smart glass. However, we aim to adopt a moderate approach and engage in scenario simulations that steer away from excessive optimism. The second reason is that a large number of windows today have external or internal blinds or externally installed light shades, and it might be interesting for the readers.

The price of normal triple glazing window and window equipped with aluminum blinds are considered to be 550 €/m2 and 800 €/m2. Note that MEMS smart glass can be supplied according to customer requirements in different categories from standard to premium and in different price ranges. For the simulations an average cost of 1,550 €/m2 has been considered. This is the average cost ranging from standard to premium embodiment of the window.

In MEMS smart windows, tailored light guiding is possible due to the development of sub-field addressing in micromirror arrays[23], thus the whole window module is segregated into 36 subfields, each having 1 m2 area. A constant temperature of 20 °C and 500 lx of illuminance per m2 is maintained in the room by the required lighting, heating, and air-conditioning appliances (Table 8).

| Specification | |

| Light fixtures | 49800 lm |

| Heater | 10720 W |

| Air conditioner | 5.3 t |

The electricity cost per kWh is assumed to be 0.40 €[94]. Based on the requirement as mentioned above for the model room, the initial investment on the lighting, heater and AC is considered to be 21,186 €, 24,300 € and 31,250 € respectively with window blinds and 18,000 €, 22,599 € and 27,500 € respectively with MEMS smart window. Since MEMS smart window enables proper distribution of daylight and solar radiation, the engine power (The wording “engine power” means “engine size” or “engine class”) for light, heater and air conditioner is reduced by 15% compared to the windows equipped with aluminum blinds. Due to the energy saving capacity of MEMS smart glass, the engine class does not need to be as large as for window with aluminum blinds. The simulation results without any engine class reduction as well as several combinations of engine class reduction have been presented[16]. Since we simulated a potential to save up to 35%, we chose a reduction value which is moderate in comparison to 35%. We are aware that by using another combination of the multiple input parameters, we would obtain a different simulation result. We cannot simulate and report on all possible combinations. In a proper scientific way, we provide all the used input parameters.

A TRY database is used in our calculation for Kassel, located at 51.18° N latitude, 231 m above the sea level and in the central area of northern, western and eastern low mountain ranges (up to 600 m above sea level). The database is a combination of hourly data for Kassel over the year from January 1st to December 31st recorded by the “Deutscher Wetterdienst” (German Metrological Service) from a considerably long observation period of 1995-2012. The meteorological parameters of the database are listed in Table 9. The data like temperature, cloud coverage, heat irradiance, visible irradiance, wind velocity and others are permanently recorded. Still, for all parameters, an averaged value has been saved each hour (henceforth referred to as hourly data). The methodology of the data construction in the TRY database considering a long period of time is described in EN ISO 15927- 4:2005[95].

| Parameter | Unit |

| Degree of cloud coverage | okta |

| Wind direction at a height of 10 m above ground | ° |

| Wind speed at a height of 10 m above ground | m/s |

| Air temperature at 2 m above ground | °C |

| Air pressure at station height | hPa |

| Water vapor content, mixing ratio | g/kg |

| Relative humidity at a height of 2 m above ground | % |

| Direct solar irradiance (horizontal plane) | W/m2 |

| Diffuse solar irradiance (horizontal plane) | W/m2 |

| Atmospheric heat irradiance (horizontal plane) | W/m2 |

| Terrestrial heat irradiance | W/m2 |

TRY: Test reference year.

4.1.2 Calculation methodology

The sun’s position in the sky with respect to an observer can be fully determined by two astronomical angles, solar altitude angle and solar azimuth angle. Solar altitude angle is defined as the angle between two imaginary lines from the sun to the window and the horizontal plane of the window location. This angle effectively determines the elevation of the sun in the sky. The altitude angle is correlated to the solar zenith angle and can be calculated by the equation,

where

α = altitude angle,

L = latitude angle,

h = hour angle,

φ = solar zenith angle,

δ = declination angle

n = 1 for January 1st,

n = 1 for January 2nd,

t = number of minutes from the solar noon.

The value of altitude angle (α) increases from zero in the morning, reaches its maximum in the solar noon—indicating the highest sun position in the sky and decreases to zero again in the evening. Incoming radiation from the sun is typically calculated when the altitude angle is higher than 0°, which is considered a reasonable approximation.

The solar azimuth angle (z) represents an indicator of how much the sun deviates from the due south direction in the northern hemisphere and from the due north direction in the southern hemisphere. It provides information about the horizontal direction in which the sun is located relative to a specific position of the observer on the Earth.

This equation is only applicable for the condition cos(h) > tan (δ)/tan (L). The incident angle characterizes how the sunlight strikes the window surface and determined as the angle between a perpendicular line on the window plane and the incoming light rays from the sun. The general expression for the incident angle[96] is

where

β = surface tilt angle from the horizon,

Zs = surface azimuth angle, the angle between the normal to the surface from the true south.

Since the window in this calculation is vertically oriented, the surface tilt angle (β) is considered to be 0°. Therefore, equation 3.5 is reduced to

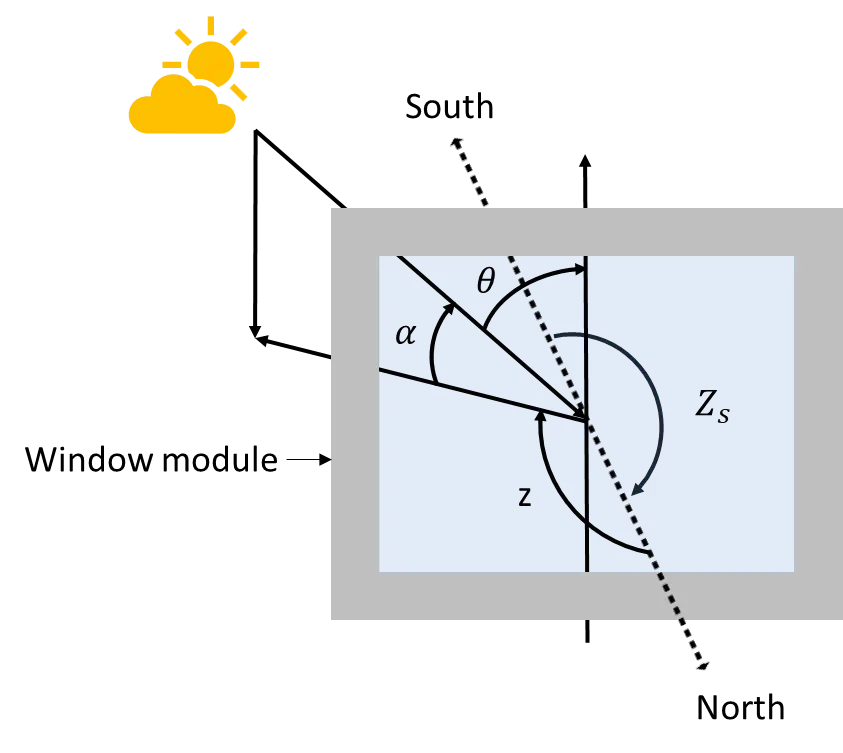

Indeed, the solar incident angle gradually decreases in the morning and reaches its minimum value at solar noon. As a result, during solar noon, the window surface receives solar radiation with the least divergence from a perpendicular vector. This means that at solar noon, the sunlight hits the window surface most directly, which can have implications for maximizing energy capture or minimizing shading effects[97,98]. The schematic representation of solar angles with respect to the south-oriented window is depicted in Figure 13. For simplicity, this calculation includes only eight different orientations, representing a range of possibilities including south, southwest, west, northwest, north, northeast, east, and southeast, by accurately determining the surface azimuth angle, denoted as Zs in equation 3.6. Depending on the surface azimuth angle, any desired window orientation can be achieved:

Figure 13. Angles to define the position of the sun with respect to a window module for a south-oriented window. Reproduced with permission from[16].

• Zs = 0° for south orientation,

• Zs = 45° for southwest orientation,

• Zs = 90° for west orientation,

• Zs = 135° for northwest orientation,

• Zs = 180° for north orientation,

• Zs = 225° for northeast orientation,

• Zs = 270° for east orientation,

• Zs = 315° for southeast orientation.

The total solar irradiance falling on the window is calculated from the TRY database by using the following equation,

where

Idirect = direct solar irradiance,

Iatm = atmospheric heat irradiance,

Iearth = terrestrial heat irradiance,

Idiffusion = diffuse solar irradiance,

N = degree of cloud coverage.

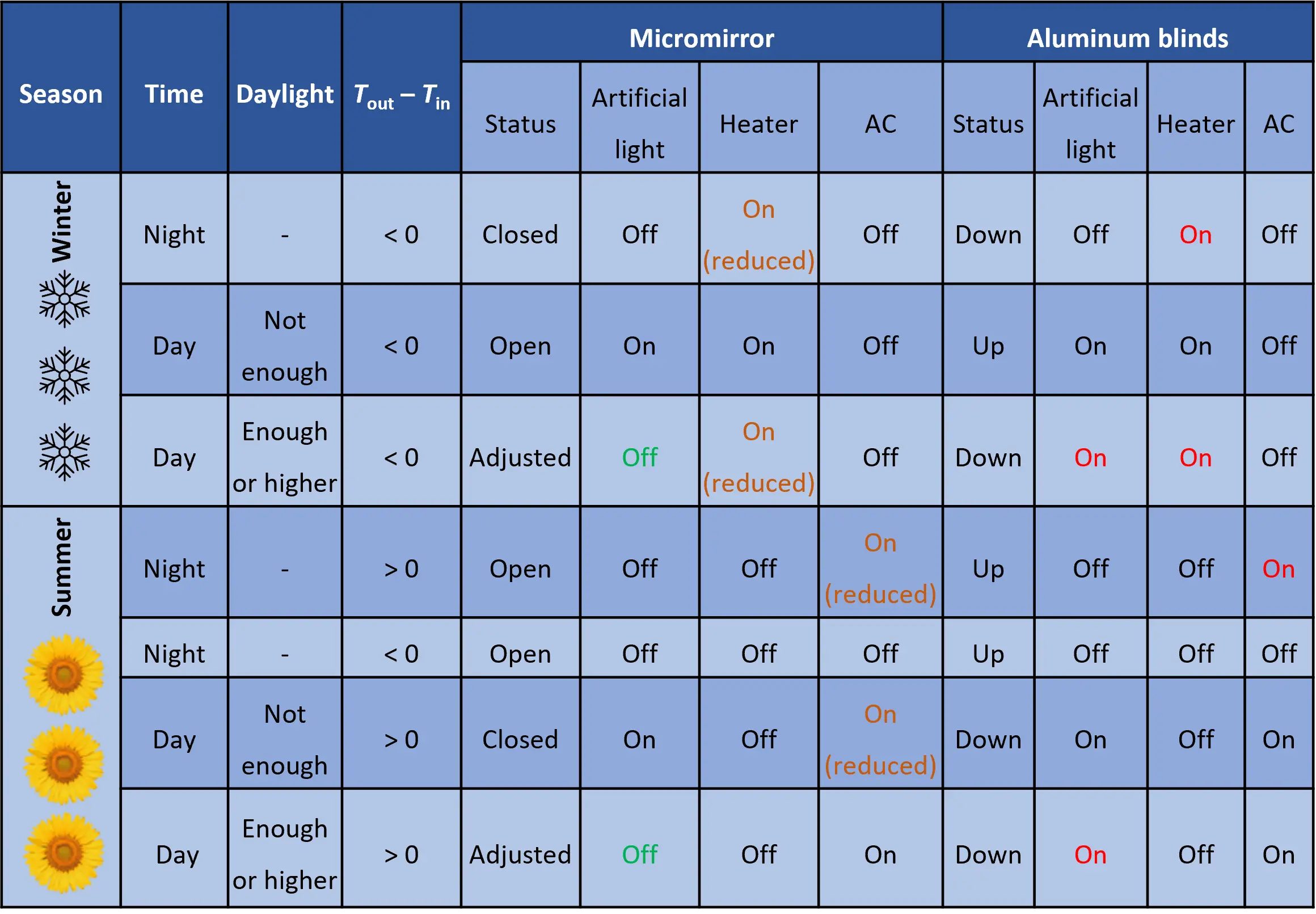

The analysis of light interactions at each interface of the triple-pane window takes into account the fractions of light that are reflected at the interfaces, which is referred to as angular reflectance. The Fresnel equations were reduced by formulating the transition equation of electromagnetic wave at the interface to determine the visible light transmission. Fresnel equations are dependent on the incident angle, relative refractive index of the interface and polarization of the incident light. Light polarization is categorized based on the orientation of the electric field. Given that angular reflection varies depending on the orientation of the electric field with respect to the window interface plane, the parallel (p) and perpendicular (s). Moreover, the p and s polarizations can be described by the parallel and perpendicular oscillation of the electric field[99]. In a triple plane window, incident light has to pass through six interfaces (air-glass, glass-argon, argon-glass, glass-argon, argon-glass, glass-air); the angular reflection is calculated at all the interfaces in Figure 14 using similar equations like (3.8) and (3.9).

Figure 14. Illustration of light travel path at every interface in a triple glazing window having argon (Ar) in the window spacing. Sunlight travel paths at the interfaces are represented by the arrows. Reproduced with permission from[28].

As an example, the angular transmission at the argon-glass interface is explained here,

where

Rp(argon-glass) = angular reflection for p light at argon-glass interface,

Rs(argon-glass)= angular reflection for s light at argon-glass interface,

ns(argon-glass)= relative refractive index at argon-glass interface.

The initial incident angle is calculated for each hour over the course of the year, representing the angle at the first argon-glass interface. However, as light travels inside the windowpanes the incident angle changes. Therefore, Snell’s law is used to calculate the incident angle at the interfaces before the sunlight reaches inside the room,